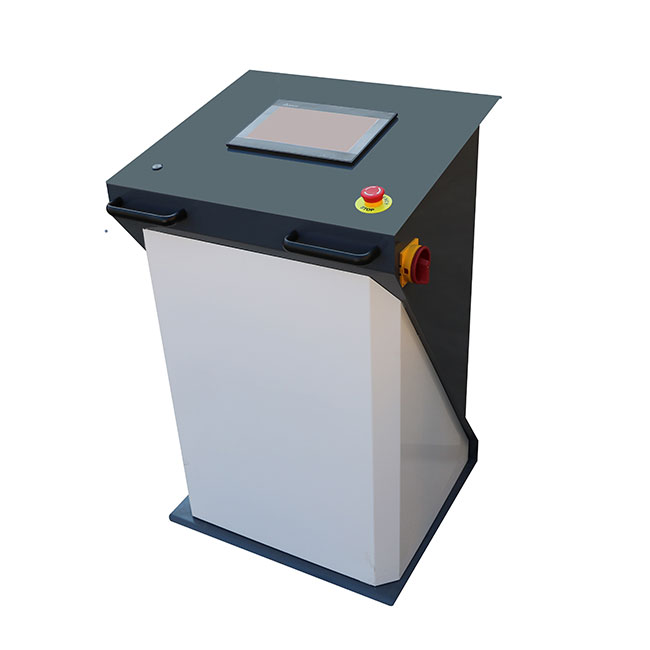

Hydrostatic Pressure Tester

Standards

Standards

ISO 1167

ASTM D 1598

ASTM D 1599

Application

It is designed to analyze the resistance of internal pressure and short-term hydraulic burst with constant internal pressure at constant temperature in plastic pipes and fittings made of PE, PVC, PEX, PVC, PP, PB, etc.,

Features

The system is a modular one and has high accuracy with any size of sample, as long as it is connected to a solenoid valve.

Moreover, it doesn't require any maintenance beyond the initial installation.

The compact and modular design of this system allows up to 20 independent pressure stations to be connected on an area of just 0.5 m2.

A further advantage is that this system consumes very little energy.

Thanks to the high pressure water hydraulic pump and big capacity pressure reservoir to ensure maximum capacity at all times.

Software Features

With functions including specimen pre-treatment, real-time monitoring, test data storage, data power-off protection as well as resuming operation once power is restored.

The measure is protected by an electric, mechanical as well as software part.

It is intelligent to distinguish the size and material of specimen, then provide perfect pressure rising solution and algorithm.

For the pipes with big rate of expansion has the properties of rapid pressure rising rate and steady at constant pressure.

Highlights

· pressure testing of even large PE pipe samples

· Burst test, internal-pressure test

· Easy to install and to operate

· High accuracy pressure control

· Online support via internet connection

Technical specifications

Output: Up to 100 , 160 bar or 200 bar

Capacity: 1 to 20 stations (30 stations on request)

Pressure resolution: 0.01 bar

Timing range: 0~10000h

Time resolution: 1s

Timing mode: Counter-up, counter-down

Associated equipment

Test tank

End closures

Laboratory saw

Standards

Standards