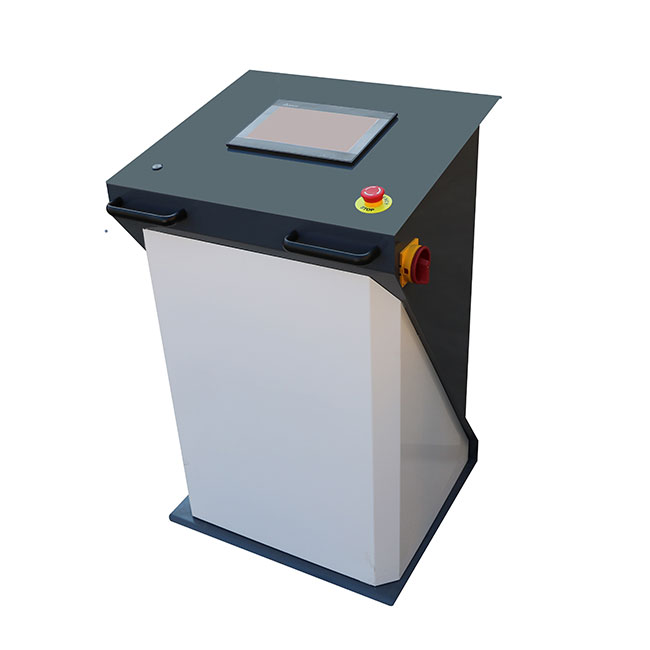

Product Overview

The Large High Pressure Hydro-static Testing Machine is a heavy-duty solution engineered for industrial hose certification in demanding environments. Capable of generating pressures up to 50,000 psi (3450 bar)—10 times the working pressure of most industrial hoses—it rigorously evaluates the burst strength and fatigue resistance of hoses used in mining, construction, and oil refineries. Its innovative dual-chamber design allows parallel testing of two hoses (up to 20ft in length), doubling throughput while ensuring compliance with ASME BPVC Section VIII (pressure vessel code) and other global safety standards.

Product Specifications

Parameter | Value |

Maximum Pressure | 50,000 psi (3450 bar) |

Test Chamber Size | Customizable up to 20ft length |

Pressure Holding Time | Up to 24 hours |

Power Source | Hydraulic motor with 2.2 hp |

Safety Rating | CE, OSHA, CSA |

Features

Ultra-High Pressure Capability: Utilizes a five-stage intensifier pump (with chrome-plated pistons) to achieve 50,000 psi with minimal energy loss, maintaining stable pressure for up to 24 hours during endurance tests.

Dual-Chamber Efficiency: Independent control systems for each chamber allow simultaneous testing of different hose types (hydraulic, chemical transfer, steam) at varying pressures, reducing overall testing time by 50% compared to single-chamber models.

Safety Interlocks: A redundant safety system—including light curtains, pressure-sensitive floor mats, and automated steel doors—prevents operator access during active tests, while a rupture disc (rated at 55,000 psi) vents excess pressure in milliseconds.

Data Acquisition System: High-speed sensors record pressure vs. time curves at 100 samples per second, with built-in software to analyze burst patterns and calculate safety margins, supporting ISO 14021 environmental claims.

Application

Manufacturing Plants: Certifying hydraulic hoses (SAE 100R15, 100R2) for excavators, cranes, and agricultural machinery, ensuring compliance with ISO 18797.

Oil and Gas: Validating subsea umbilicals (thermoplastic hoses) and offshore drilling hoses (API 7K) for resistance to seawater corrosion and pressure cycling.

Aerospace: Testing fuel hoses (PTFE) and hydraulic lines (stainless steel braided) in aircraft engines, meeting SAE AS4819 standards for high-temperature performance.