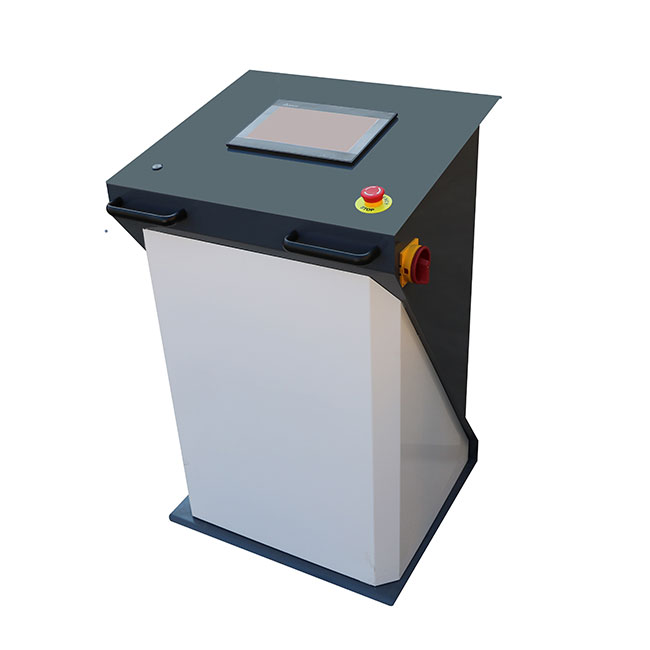

Product Overview

The Customized Hydro-static Testing Machine is a rugged, portable, explosion-proof solution purpose-built for oilfield blowout preventer (BOP) testing in remote and hazardous environments. Equipped with a manual hand pump (with a 5:1 pressure ratio) as the primary pressure source, it can generate pressures up to 20,000 psi—with optional pneumatic boosting for ultra-high pressure requirements—while strictly adhering to API 16A (blowout preventers and wellhead equipment) and ISO 13533 (petroleum and natural gas industries) standards. Its skid-mounted design, featuring corrosion-resistant aluminum alloy framing, withstands extreme temperatures (-20°C to 60°C) and exposure to saltwater, making it essential for onsite maintenance and pre-operation inspections in offshore and onshore oilfields.

Product Specifications

Parameter | Value |

Maximum Pressure | 20,000 psi (1380 bar) |

Pressure Generation | Hand pump + pneumatic booster |

Medium Compatibility | Water, oil, glycol |

Safety Features | Relief valve, pressure gauge |

Weight | 110 lbs (portable skid-mounted) |

Features

Dual-Power Operation: Combines a manual hand pump (cast iron construction, 100 strokes per minute max) for low-pressure priming (0 to 5,000 psi) and a pneumatic booster (100 psi air input) for high-pressure testing (5,000 to 20,000 psi), ensuring reliability even in areas with limited power access.

Explosion-Proof Design: Certified to Class I, Division 1, Group C/D hazardous area standards by UL and ATEX, with spark-resistant components and a flame-arresting pressure gauge to prevent ignition in volatile environments.

Real-Time Monitoring: Integrates a digital pressure transducer (0.1% full-scale accuracy) with a 4.3-inch sunlight-readable display, logging pressure data at 1-second intervals for post-test analysis and regulatory compliance.

Easy Maintenance: All wetted components—including hoses and valves—are constructed from 316 stainless steel, while quick-disconnect fittings allow for tool-free replacement of wear parts, reducing maintenance time by 50%.

Application

Oilfield Operations: Testing blowout preventers (annular and ram types), wellhead valves, and subsea pipelines (up to 12-inch diameter) during drilling rig commissioning and periodic inspections.

Fire Protection Industry: Validating the integrity of high-pressure fire extinguisher cylinders (CO₂, dry chemical) and sprinkler system risers, meeting NFPA 1962 standards.

Mining Sector: Inspecting high-pressure hydraulic hoses and control valves used in underground drilling equipment, ensuring compliance with MSHA safety regulations.