Product Overview

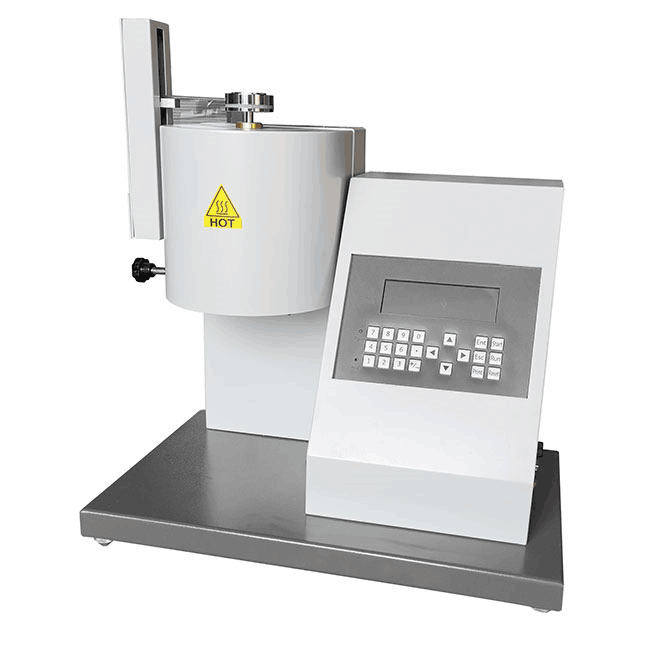

The Best Price Extrusion Plastometer for Rubber With CE delivers exceptional value without compromising on performance, making professional-grade rubber testing accessible to small manufacturers, research labs, and educational institutions. Specifically designed to measure Mooney viscosity—a key indicator of rubber processability—and cure characteristics, this instrument is certified to ISO 289:2015 and ASTM D1646-19, ensuring data comparability with global standards.

Powered by a 1500W heating system with ±0.5°C temperature control, it maintains stable test conditions for accurate measurement of scorch time (t5), cure time (t90), and minimum/maximum torque values. The CE certification guarantees compliance with EU safety directives (EN 61010-1:2010) and electromagnetic compatibility requirements, making it suitable for international markets. Balancing affordability with reliability, this plastometer eliminates the need for expensive equipment while delivering results you can trust.

Features

Cost-Effective Performance

Mooney Viscosity Testing: Measures ML (minimum torque) and MV (maximum viscosity) in Mooney units (MU), with a range of 0–200 MU for most rubber compounds.

Cure Analysis: Automatically calculates scorch time (t5: time to 5% torque increase) and cure time (t90: time to 90% cure) for quality control of vulcanization processes .

Temperature Range: 50°C to 200°C in 1°C increments, covering natural rubber, synthetic rubbers (SBR, EPDM), and rubber composites.

User-Friendly Design

LCD Display: 2.4-inch backlit screen showing real-time temperature, torque, test duration, and calculated results, with simple button controls for easy operation.

Manual Extrudate Cutting: Spring-loaded cutting tool with adjustable timing (1–60 seconds) for collecting extrudate samples during viscosity testing.

Compact Benchtop Design: Measures 400×300×500mm and weighs 25kg, fitting easily in small laboratories or production floor quality control stations.

Safety and Compliance

CE Certification: Meets EN 61010-1:2010 for electrical safety, including overload protection and safe insulation distances between live parts .

Thermal Protection: Ceramic fiber insulation around the test chamber reduces external temperatures to <40°C during operation, preventing burns.

Applications

Rubber Manufacturing:

Quality control of raw rubber incoming from suppliers to ensure consistent viscosity.

Optimizing rubber compound formulations by testing the effect of curatives, fillers, and plasticizers on cure behavior.

Automotive Industry:

Testing the viscosity of tire tread compounds to ensure uniform extrusion during manufacturing.

Evaluating the cure characteristics of gaskets and O-rings to prevent under/over-vulcanization.

Academic Research:

Studying the impact of recycling on rubber properties by comparing Mooney viscosity of virgin vs. recycled materials.

Teaching rubber technology principles, including vulcanization kinetics and processability.

Recycling Sector:

Assessing the reprocessability of rubber crumb from tire recycling by measuring viscosity changes after multiple processing cycles.

FAQ

Q: What is the torque measurement range of the instrument?

A: It measures torque from 0.1 to 20 N·m with a resolution of 0.01 N·m, covering the typical range for most rubber compounds .

Q: How long does a complete Mooney viscosity test take?

A: A standard test (preheat 1min, test 4min) takes 5–6 minutes, with cure time tests ranging from 10–30 minutes depending on the rubber’s cure rate .

Q: Can it test rubber compounds with high filler content (e.g., carbon black)?

A: Yes, the robust rotor design and hardened steel die withstand abrasive fillers, though we recommend more frequent cleaning to prevent buildup .

Q: Is training required to operate the plastometer?

A: Basic operation can be learned in under an hour with our user manual and tutorial videos; we also offer optional on-site training for $200 per session .

Q: What is included in the standard package?

A: The package includes the plastometer, standard rotor (38.1mm diameter), 2.095mm die, calibration weights, user manual, and CE certificate of conformity .