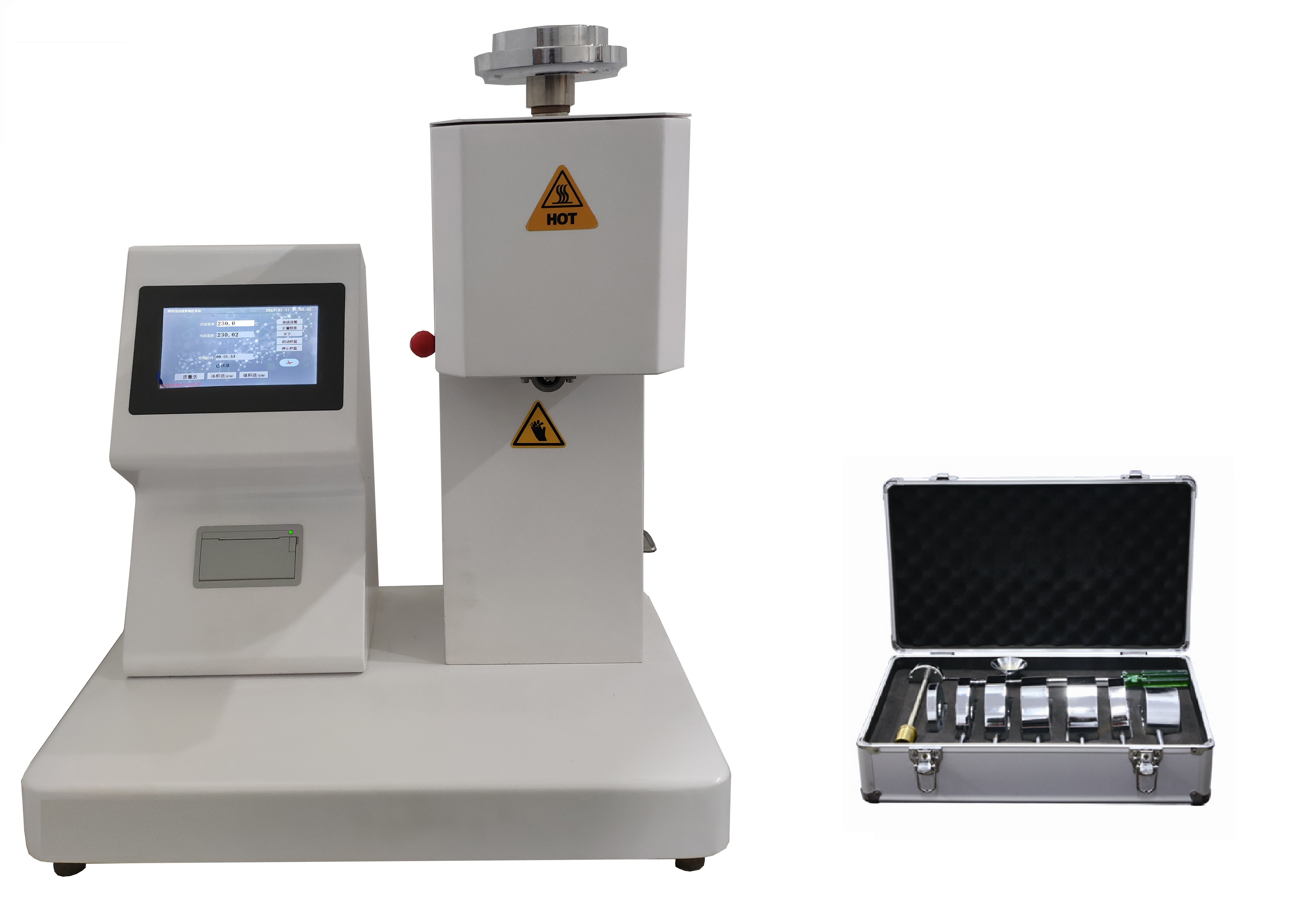

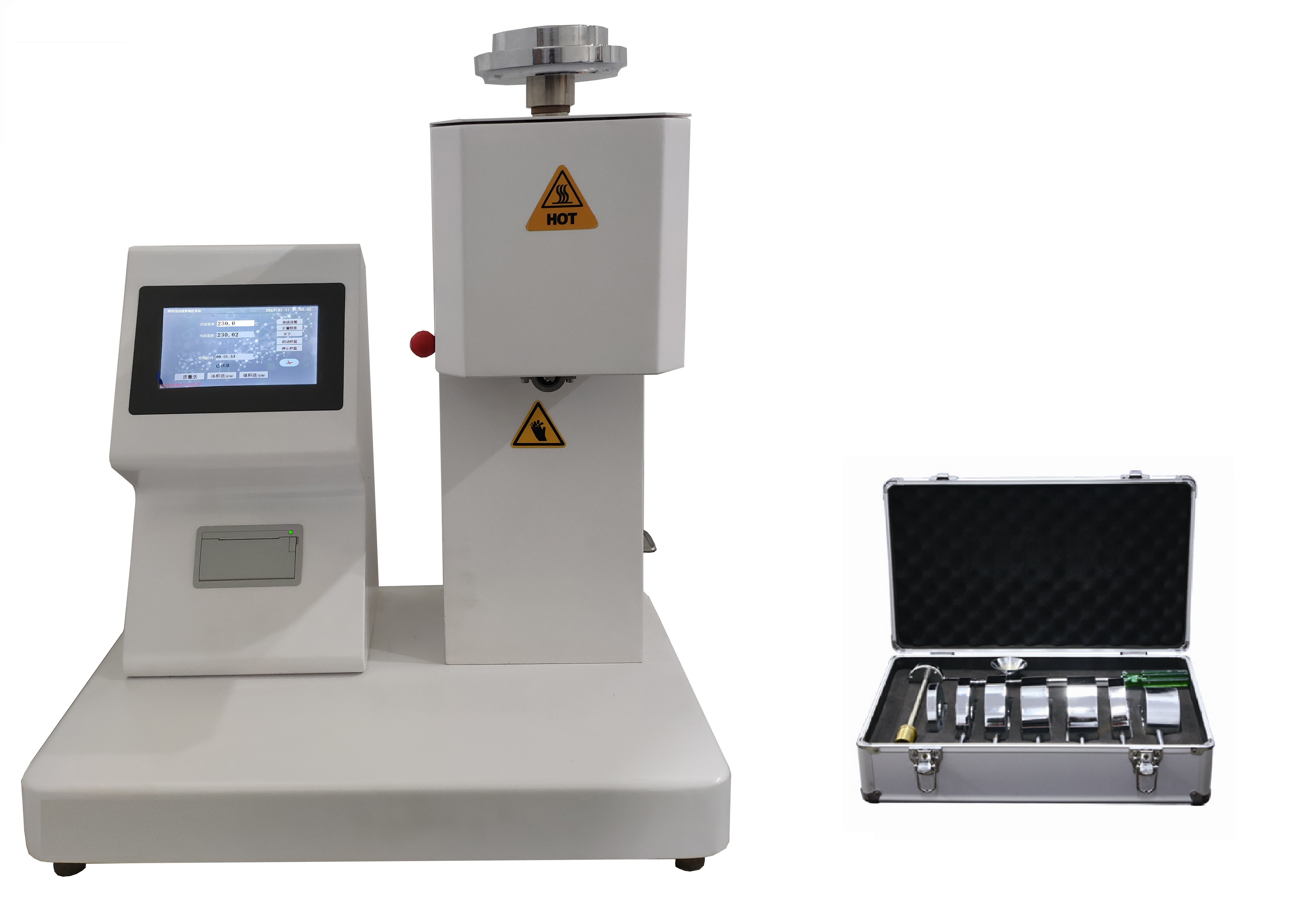

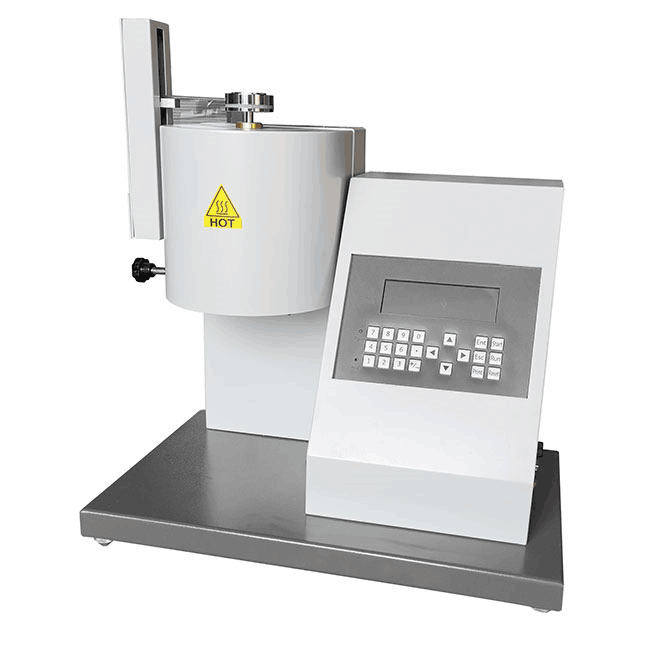

Melt Flow Indexer GT-MFI-450D

Melt Flow Indexer GT-MFI-450D

Standards

The tester is far superior to all national and international standard of Melt Flow Rates requirements, including ISO1133, ASTM D1238 and GB/T 3682 method A & B.

Application

With this compact and cost-effective device, you can test melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastic raw materials, including grains, strips, films, etc. This test method could be very useful for quality control on thermoplastics.

MVR measurements are particularly useful when comparing materials of different filler contents and when comparing thermoplastics that are filled or unfilled. MFR can be determined from MVR measurements if the melt density is known at the test temperature and pressure.

High Accuracy

The built-in microprocessor maintains temperature control to within ± 0.5℃, with rapid ram-up to the set point. Extruded material is automatically cut off by the built-in scraper mechanism at preset intervals, controllable to ± 0.1second.

Ease to operate!

It has never been easier or more economical to test melt flow rates! The tester is complete with the accessories and weights necessary for maintenance and operation. All you need to do is plug it in and start testing!

Technical Parameters

Technical Parameters

Operating temperature: 50 ℃ to 450℃

Temperature control accuracy: ≤0.2℃

Temperature display resolution: 0.1℃

Control mode: 7” colorful touch screen and PC

MVR displacement accuracy: 0.02mm

Temperature recovery time: <4 min

Power supply: 220V 50Hz

Communication port: RS485 / USB

Temperature measuring points: 2

Measurement range:(0.1-100)g/10min /(0.01-350)cm³/10min

Features

MVR test methods evaluate the MVR value of samples after a specified amount of time, and MFR values are determined after weighing the sample. Melt density can also be calculated.

The MFI device can be controlled by 7” colorful touch screen, as well as computer via application software.

The application software has the functions of parameter setting, constant temperature control, cutting, calibration, timing, display of MFR and MVR results, calculation of melt density, and query and export of test data.

In order to prevent misoperation, some important operations require password verification.

Fast heating rate, small overshoot, high constant temperature accuracy, quickly restore the constant test temperature. With upper limit temperature protection, constant temperature voice prompt, restore time voice prompt.

Standard configuration

1. Piston Rod

2. Die

3. Die Cleaning Tool

4. Cut-off Knife

5. Cylinder Cleaning Tool

6. Sample Charging Tool

7. Lever Meter

8. Funnel

9. Cylinder

10. Weights (up to 21.6kg)

OUR SERVICE

We have 20-year expericen design team

We have professional QC team to ensure product quality

We have skilled staff to provide you perfect finished products

We provide you ontime aftersale service