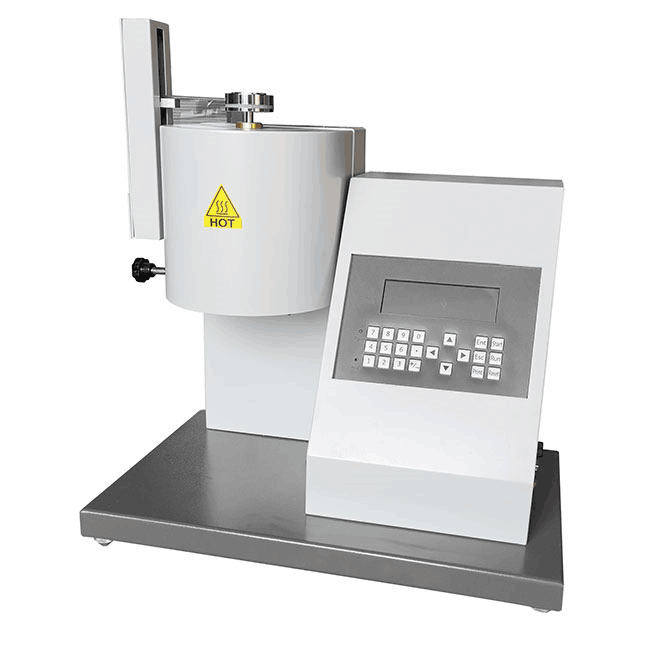

Product Overview

The Electronic Extrusion Plastometer for Laboratory With CE emerges as an indispensable tool for material characterization, specializing in the precise measurement of melt flow rate (MFR) and melt volume flow rate (MVR)—key indicators of a material’s processability in extrusion and injection molding. Meticulously calibrated to ISO 1133-1:2011 and ASTM D1238-20, this instrument delivers data with a repeatability of ±2% and reproducibility of ±5%, ensuring compliance with global quality standards.

At its core lies a 2000W ceramic heating system that achieves target temperatures (120°C to 400°C) in under 15 minutes, with ±0.3°C stability maintained via a closed-loop PID controller. The CE certification underscores its adherence to EU directives, including safety (EN 61010-1) and electromagnetic compatibility (EN 55014-1), making it suitable for integration into regulated laboratory environments. Whether analyzing virgin polymers, recycled materials, or composites, this plastometer provides actionable insights into viscosity behavior under controlled shear and temperature conditions.

Features

Advanced Testing Capabilities

MFR/MVR Measurement: Supports both gravimetric (MFR, g/10min) and volumetric (MVR, cm³/10min) testing, with automatic calculation of results based on ISO/ASTM procedures.

Temperature Range: 120°C to 400°C in 1°C increments, covering materials from low-density polyethylene (LDPE) to high-performance engineering plastics like PEEK.

Load Range: 0.325 kg to 21.6 kg via interchangeable weights, enabling testing of materials with melt viscosities ranging from 10 to 10,000 Pa·s .

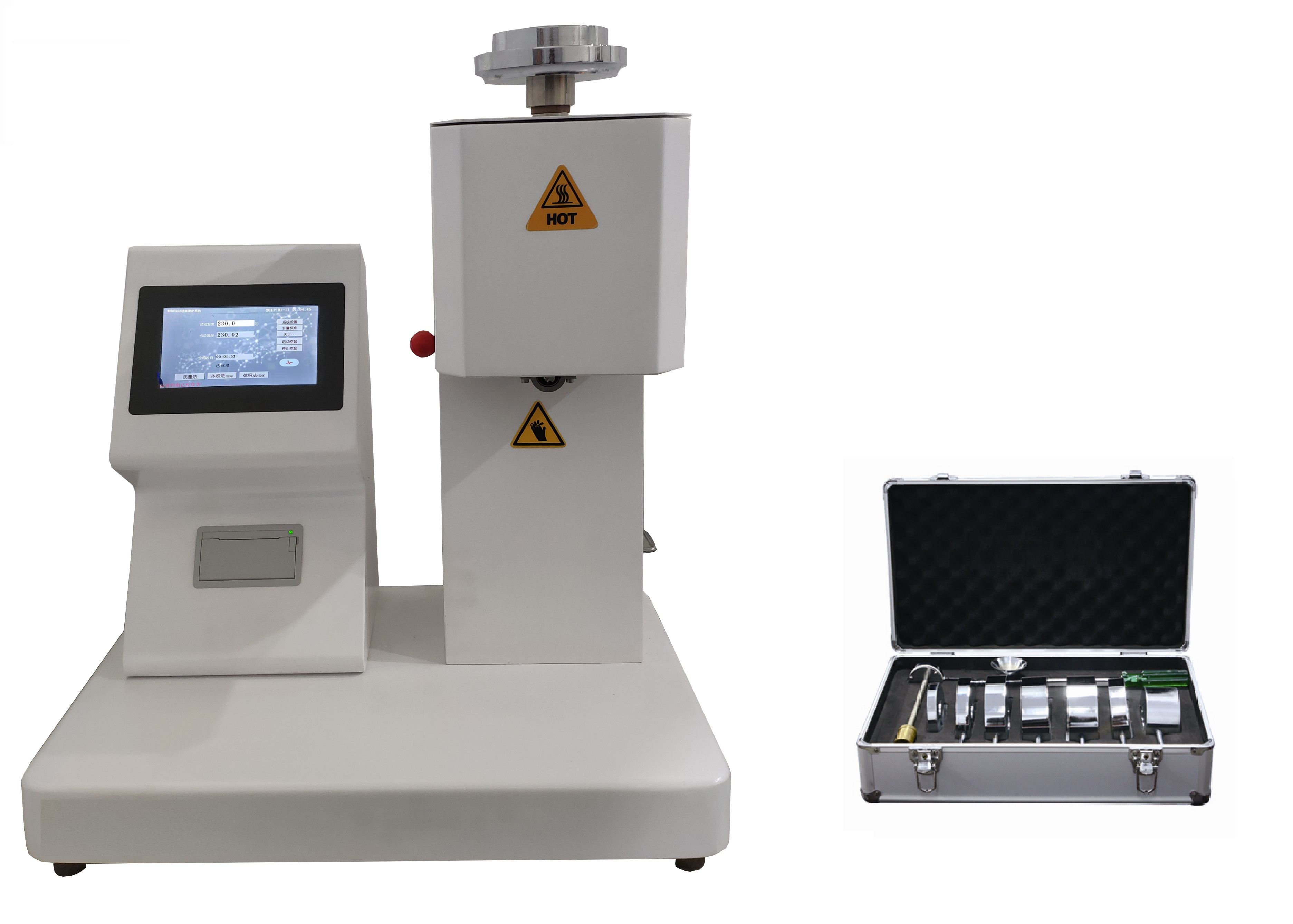

User-Friendly Design

Touchscreen Interface: 5-inch color display with intuitive menus for setting test parameters (temperature, load, preheat time), displaying real-time data, and viewing test history.

Data Logging: Internal memory stores 1000 test records with timestamps, sample IDs, and operator codes, exportable via USB in CSV or PDF format for integration with LIMS.

Quick-Change Components: The 9.55mm diameter barrel and standard dies (2.095mm ISO, 0.0825in ASTM) feature tool-free installation, reducing downtime between material changes to under 5 minutes .

Safety and Compliance

CE Certification: Validated for compliance with 2014/35/EU (LVD) and 2014/30/EU (EMC) directives, with ESD protection for reliable operation in electronics manufacturing environments .

Over-Temperature Protection: Independent thermal fuse and software-based cutoff activate if temperature exceeds setpoint by 15°C, preventing material degradation or fire risk.

Safety Enclosure: Reinforced polycarbonate guard surrounds the extrusion area, with interlock switches that pause operation if opened during testing .

Applications

Plastics Manufacturing:

Incoming quality control of resin pellets to ensure consistency between batches.

Optimizing processing parameters for extrusion of films, pipes, and profiles by correlating MFR with machine settings.

Rubber Industry:

Evaluating the flow behavior of thermoplastic elastomers (TPEs) during compound development.

Monitoring the effect of additives (plasticizers, fillers) on melt viscosity in rubber compounds.

Research Laboratories:

Studying the impact of thermal history on polymer degradation via MFR changes after aging.

Characterizing bio-based polymers and their processability compared to petroleum-based alternatives.

Academic Institutions:

Teaching fundamental principles of polymer rheology through hands-on MFR experiments.

Supporting student research on sustainable materials and recycling technologies.

FAQ

Q: What is the minimum sample size required for a test?

A: A 5–10g sample is sufficient for most materials, with a recommended pellet size of 3–5mm to ensure smooth feeding into the barrel .

Q: Can the instrument test filled polymers with glass fibers or carbon black?

A: Yes, but we recommend using the optional wear-resistant tungsten carbide die for extended lifespan when testing abrasive filled materials .

Q: How often is calibration required to maintain accuracy?

A: Annual calibration with certified reference materials (e.g., ISO 1133 standard polyethylene) is recommended, though the instrument includes a built-in self-calibration function for monthly verification .

Q: Is the software compatible with Windows and macOS?

A: The companion software runs on Windows 10/11 and macOS 12+, enabling remote control, data analysis, and report generation .

Q: What is the power consumption during operation?

A: Peak power is 2000W during heat-up, dropping to 500–800W during steady-state testing, making it energy-efficient for continuous use .