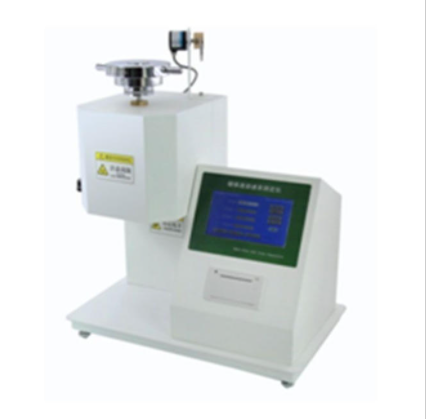

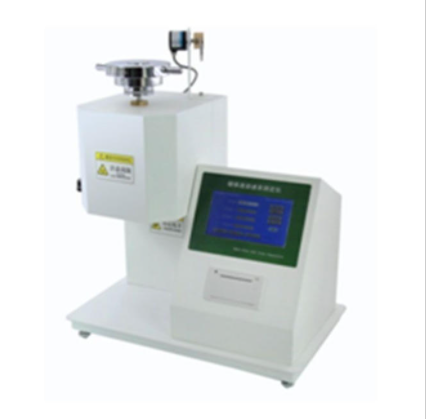

Melt flow index machine has been very widely used in plastic raw material production, plastic products, petrochemical industry, and other industries as well as relevant universities and colleges, scientific research departments, and commercial inspection departments. Through the microprocessor according to the standard test process for programmed settings, it can quickly heat up and has a high precision of a high thermostat. After the packing, it can make the constant temperature state recover quickly. There are many functions, such as Chinese display, automatic timing, automatic material cutting, automatic calculation, automatic printing, etc.

Here is the content list:

Test before start-up

According to the past use of the spring due to the humidity, the failure rate of the temperature sensor also increased, under normal circumstances, the temperature of the instrument for room temperatures, such as the occurrence of large temperature fluctuations or the temperature displayed by the instrument and the actual environment is very different, then please contact the manufacturer after-sales, we can provide guidance. Printer for thermal printers, all print paper is also thermal paper, the thermal paper has the characteristic that the carbon on the paper is extremely easy to volatilize, mainly by the humidity and temperature, in addition, we turn on the trial printing, first observe whether the printer is always on, and then print whether there is paper action, such as action on the print paper but does not show the word, then it can be judged that the print paper is damp resulting in toner volatilization, this situation requires replacement for the open paper, so usually pay attention to keep the printing paper dry.

Working environment

The working environment and conditions of the melting index instrument should fully meet the requirements, including room temperature, relative humidity, power supply voltage, installation base (the surrounding of the machine generally requires no vibration, no corrosive media, no strong electromagnetic field interference), in addition, some instruments have special requirements for the environment, should be strictly following the instruction manual for maintenance and repair.

Keep clean

Before and after the use of the melt flow index instrument should be kept clean and avoid a collision; long not to use the melt flow index instrument, it is appropriate to plug in and start regularly.

Dedicated person in charge

Melt flow index machineshould be in charge of a person, the test should be carried out in strict accordance with the operating procedures, it is strictly prohibited to do tests beyond the scope of the test, the test should be completed to restore the instrument to the initial position, to ensure that the next test is normal.

In addition, our company also provides High Precise Charpy Impact, Good Quality PVC Pipe Falling Weight Impact Tester products.

Regular care

The melt flow index machine should be cleaned and inspected regularly, and the instrument that needs to be calibrated should be calibrated to ensure the accuracy of the instrument; according to the relevant provisions of the national metrology law, the general calibration cycle is one year.

The melt flow index machine should take appropriate protection measures when it is not in use, and if it is not used for a long time, it should be re-tested before use when it is used again. About calibration: Regular calibration, according to the relevant provisions of the National Measurement Law, the general calibration cycle is one year.

Golden Time Technology Development Limited is an excellent provider of melt flow index instrument manufacturers, in addition to the melt flow index instrument, our company also produces MFI test equipment, melt flow index instruments, melt flow tester, Mfi instruments. MFI test er, Mfi instrument. If you are interested in more information, please visit our official website www.polymer-test.com.