Introduction

When it comes to ensuring the durability and reliability of PVC pipes, rigorous testing is essential. The ASTM D 2444 standard for drop impact testing provides a crucial method for evaluating how PVC pipes withstand impacts, which is particularly important for pipes used in demanding environments. The ASTM D 2444 Drop Impact Tester plays a key role in this process by simulating real-world impact scenarios to test the resilience of PVC pipes. This article explores how the ASTM D 2444 Drop Impact Tester enhances PVC pipe testing for durability and why it's indispensable for manufacturers and quality control teams in the plastics and construction industries.

What is the ASTM D 2444 Drop Impact Test?

The ASTM D 2444 standard is a testing method used to determine the impact resistance of thermoplastic pipes, including PVC (Polyvinyl Chloride). This test is essential for assessing the ability of PVC pipes to endure sudden impacts that could cause cracking or breaking. The ASTM D 2444 standard is particularly useful for pipes that will be subjected to rough handling during installation or in service conditions.

In the test, a specified weight is dropped onto the pipe from a fixed height to assess its resistance to impact. The results provide valuable data on the pipe’s toughness and durability, which are essential for understanding how well the pipe will perform under real-world conditions.

How the ASTM D 2444 Drop Impact Tester Works

The ASTM D 2444 Drop Impact Tester utilizes a simple yet effective mechanism for simulating impacts. The test involves a falling weight that is dropped onto a PVC pipe sample placed on a rigid support. The energy from the weight’s fall is absorbed by the pipe, and the tester measures how the pipe responds to this impact.

The falling weight impact tester is designed to conform to the ASTM D 2444 standard, ensuring consistent results across testing scenarios. The key components of the tester include:

A drop weight with adjustable mass to meet specific testing requirements.

Adjustable height for the drop to control the energy level of the impact.

Support structure for the pipe sample, ensuring stability during the test.

This setup allows manufacturers to simulate the impact scenarios that pipes might face during transportation, handling, or installation.

The Importance of PVC Pipe Durability

PVC pipes are widely used in construction, plumbing, and industrial applications due to their affordability, versatility, and resistance to corrosion. However, these pipes can still be vulnerable to impact damage, especially during handling or when exposed to extreme conditions.

Ensuring that PVC pipes can withstand impacts without cracking or breaking is crucial. Pipes that fail during use can cause costly repairs, disruptions in service, and potential safety hazards. By using the ASTM D 2444 Drop Impact Tester, manufacturers can ensure that their PVC pipes meet the required durability standards and perform optimally in real-world applications.

Advantages of Using the ASTM D 2444 Drop Impact Tester for PVC Pipes

1. Reliable Durability Assessment

One of the primary advantages of using the ASTM D 2444 Drop Impact Tester is its ability to provide a reliable measure of a PVC pipe's durability. This standardized test simulates real-world impact conditions, providing manufacturers with accurate data on how their products will hold up in the field. This is essential for ensuring that pipes meet industry standards and customer expectations for performance.

2. Enhanced Quality Control

For manufacturers, quality control is a top priority. The ASTM D 2444 test allows for consistent quality testing of every batch of pipes produced. This helps to identify any defects or inconsistencies in the material or manufacturing process that could compromise the pipe's impact resistance. By identifying issues early in production, manufacturers can improve the quality of their pipes and reduce the likelihood of field failures.

3. Improved Product Design

The results from the ASTM D 2444 Drop Impact Test provide valuable insights into the structural integrity of PVC pipes. Manufacturers can use this information to refine their pipe designs, such as adjusting wall thickness or material composition, to improve impact resistance. By optimizing the design based on test results, manufacturers can produce more durable pipes that meet or exceed industry standards.

4. Compliance with Industry Standards

The ASTM D 2444 standard is widely recognized in the industry, and many regulatory bodies require that PVC pipes meet specific impact resistance criteria. By conducting drop impact testing, manufacturers can ensure that their products comply with these industry standards, helping them gain certifications and enhance their reputation in the marketplace.

5. Cost-Effective Testing

The drop mass impact tester is an efficient and cost-effective way to assess the impact resistance of PVC pipes. Unlike more complex testing methods, the ASTM D 2444 test is relatively simple to perform and requires minimal equipment. This makes it a cost-effective solution for manufacturers looking to perform regular durability testing without significant investment in expensive machinery.

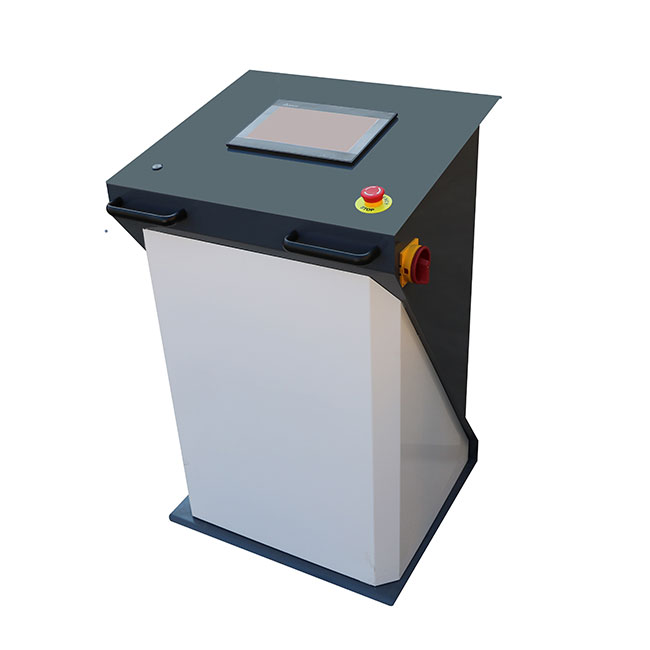

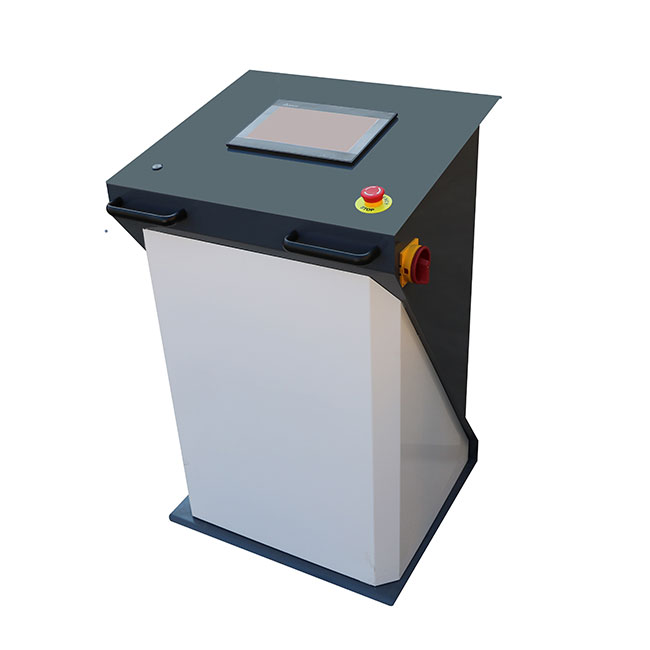

Key Features of the ASTM D 2444 Drop Impact Tester

When selecting a drop impact tester, it’s important to consider several key features that ensure the tester meets the required standards for testing PVC pipes. Some of the essential features to look for in a high-quality drop mass impact tester include:

Adjustable drop height and weight capacity: These features allow the tester to simulate a variety of impact scenarios, ensuring that the test results are relevant to real-world conditions.

Precise measurement of impact energy: Accurate measurement of the impact energy is essential for determining the pipe’s resistance to impact.

Durable and robust construction: The tester itself must be built to withstand the forces generated during testing and provide reliable results over time.

Ease of use: The best testers are designed to be user-friendly, with clear instructions and intuitive controls that simplify the testing process.

For more information on high-quality and affordable drop mass impact testers, check out these products:

Conclusion

The ASTM D 2444 Drop Impact Tester is an indispensable tool for ensuring the durability and reliability of PVC pipes. By simulating real-world impact conditions, this tester provides manufacturers with valuable insights into how their pipes will perform in the field. Whether it's for improving product design, enhancing quality control, or ensuring compliance with industry standards, the ASTM D 2444 test plays a crucial role in the PVC pipe manufacturing process.

By investing in a reliable drop mass impact tester, manufacturers can guarantee that their PVC pipes meet the rigorous demands of modern construction, plumbing, and industrial applications. The tester not only enhances product quality but also ensures that PVC pipes are able to withstand the impacts and stresses they may encounter during installation and service.

For more information about reliable and precise impact testing equipment, visit Polymer Test.