Invented in the 1950s, the melt flow indexer, or MFR, is an essential tool for plastics manufacturers. This article will explain what the MFR is, how it works, and how extrusion plastometers have become increasingly important in the plastics industry.

what is extrusion plastometer (melt flow indexer, MFR, MVR)

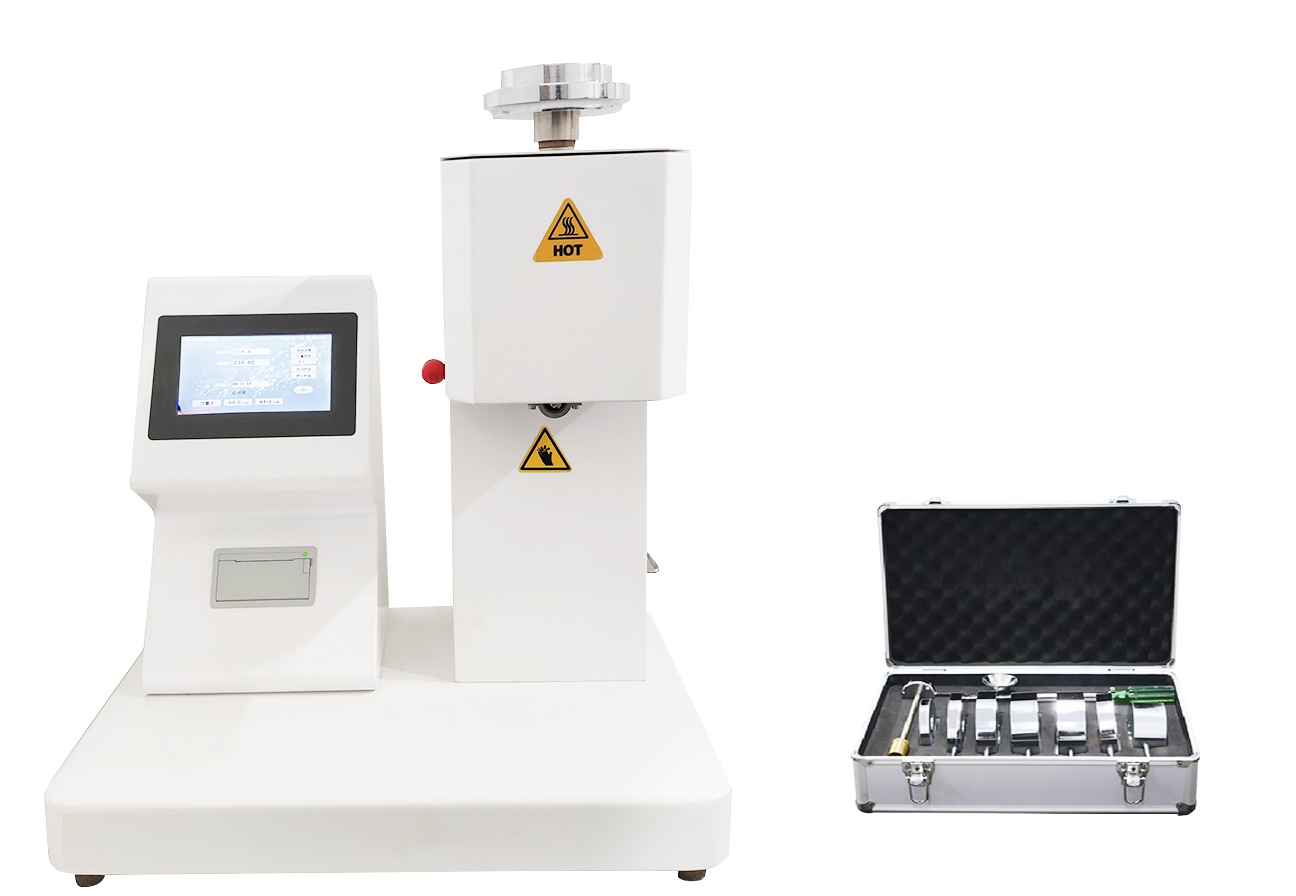

Extrusion plastometers are devices used to measure the flow rate of molten plastic. They are also known as melt flow indexers or MFRs. MVR is an acronym for melt volume rate.

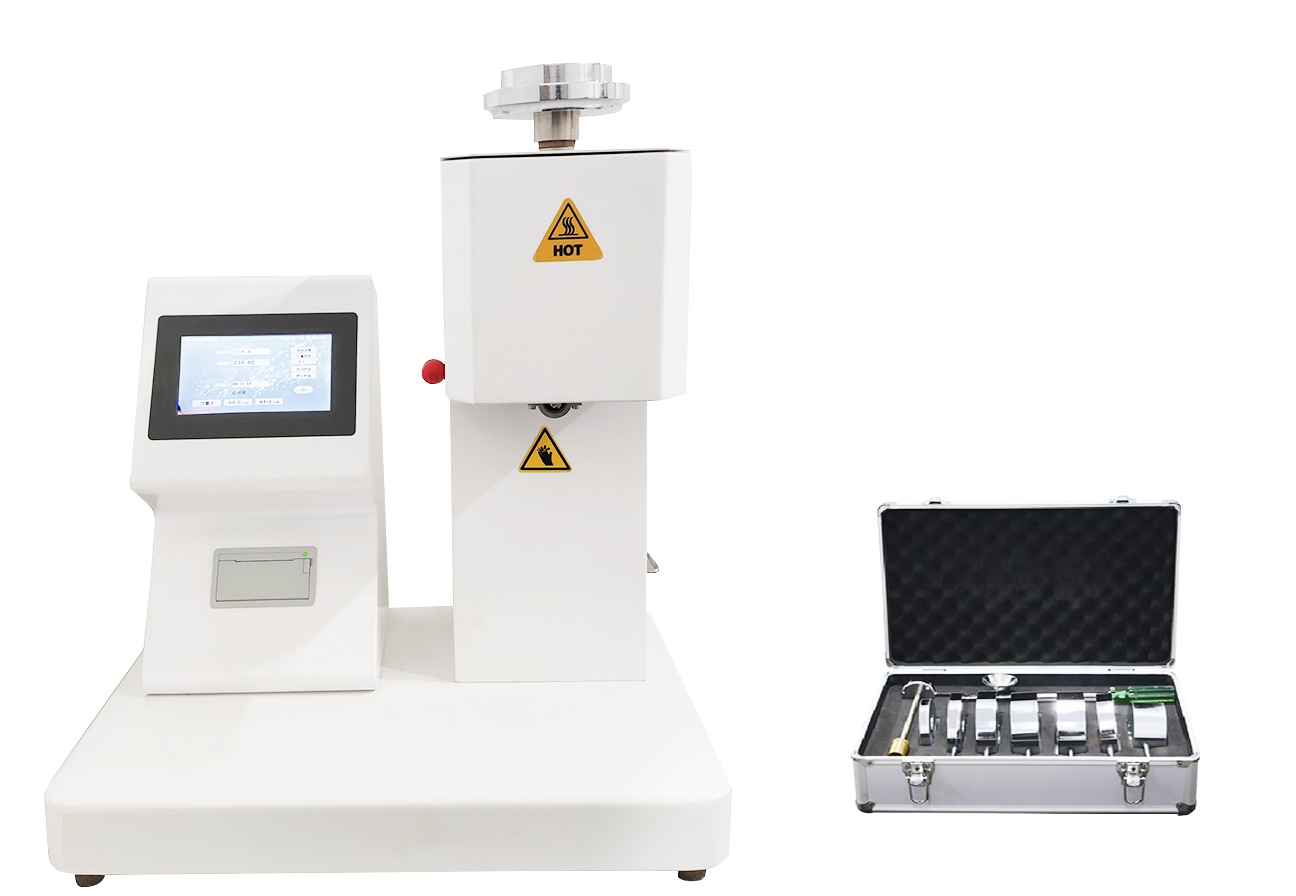

Extrusion plastometers consist of a heated barrel and a piston. The molten plastic is fed into the barrel and the piston is used to push the plastic through a small die. The resulting strand of plastic is weighed and the flow rate is calculated.

Extrusion plastometers are used to quality control during the manufacturing process, as well as to research and develop new plastics.

how do extrusion plastometer (melt flow indexer, MFR, MVR) work

Extrusion plastometers are devices used to measure the flow of molten plastic. The most common type of extrusion plastometer is the melt flow indexer, which uses a piston to push molten plastic through a small orifice. The MFR measures the amount of plastic that flows through the orifice in a given period of time and is typically expressed in grams per 10 minutes.

MFR is a good indicator of the viscosity of molten plastic, but it does not take into account the pressure drop across the orifice. The melt flow rate can be affected by changes in temperature, so it is important to maintain consistent conditions when running tests. The MVR test measures the amount of volumetric flow of molten plastic and is not affected by changes in temperature.

Melt flow indexing is an important quality control tool for plastics manufacturers. It can be used to monitor process conditions and ensure that products meet specifications.

what is the difference between different extrusion plastometer

When it comes to measuring the flow of molten plastic, there are three main methods: melt flow indexer (MFI), melt volume rate (MVR), and extrusion plastometer (EP). All three of these methods are used to determine the ease with which molten plastic flows, but they each have their own advantages and disadvantages.

MFI is the most commonly used method for measuring flow. It is quick and easy, and provides a good estimate of how well a plastic will flow. However, MFI does not take into account the viscosity of the molten plastic, which can be a significant factor in determining flow.

MVR is similar to MFI in that it measures the rate at which molten plastic flows. However, MVR takes viscosity into account, which makes it a more accurate measure of flow than MFI. The downside of MVR is that it is more expensive and time-consuming than MFI.

EP is the most accurate method for measuring flow, but it is also the most expensive and time-consuming. EP measures both the rate at which molten plastic flows and the pressure required to keep the flow constant. This makes EP ideal for measuring highly visc