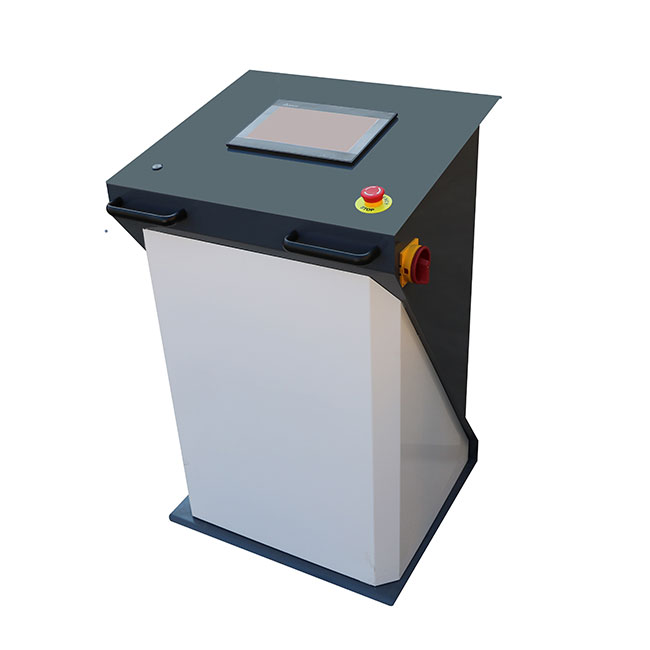

Testing Equipment for Drip Irrigation Tape and Emitting Tube

Standards

l ISO 9260

l ISO 9261

Application

This device is used to determine the flow uniformity, pressure and flow relationships, hydrostatic pressure tests at constant temperatures, hydrostatic pressure tests at high temperatures, burst tests on drip irrigation tubes with labyrinth on one side, and to test compensating emitter.

Additionally, it is suitable for burst testing, hydrostatic testing, and water supply irrigation soft tubes. It is easy to operate, and the entire test procedure is automatically controlled.

Features

Ø Automatic volume flow measurement: With the intelligent volume flow measuring sensor, the volume flow can be measured directly with high accuracy.

Ø Multi-functions: flow uniformity, pressure & flow relationship, hydrostatic pressure test, hydrostatic pressure test at high temperature, as well as burst test.

Ø High test efficiency: several test programs are embedded, the whole procedure will be controlled automatically without any intervention. Data can be saved automatically & data is held on when power is turned off.

Ø Automated information processing: Automatically measuring the dripping time & dripping capacity of each emitter, Automatically calculating of Mean Flow, Coefficient of Variation (CV), Deviation between Mean Flow and Rating Flow, Adjacent two drip flow difference, as well as automatically sorting 25 emitters.

Ø Pressure and Flow Relationship Test: Automatically control the test pressure without overstriking. While pressure is stable, the system can measure all the flow volume at different pressures. After all the pressure points are performed, Automatically calculating the Flow Constant K, Flow Index m, as well as Flow Q.

Ø Energy Saving and Environmental Protection: Water measured by volume flow sensor can be recycled after test.

Technical Parameters

1. Test station number: 5 ( each station providing with 5 sets of volume flow sensors for measuring flow uniformity, flow & pressure relationship, hydrostatic pressure and burst tests);

2. Volume flow is measured by sensor, far more better than balance or load cell;

3. Volume flow sensors : 25 pieces ( simultaneous measurement) ;

4. Timing accuracy: ±0.1s;

5. Flow range: 1.00l/h~3.60l/h;

6. Irrigation tube (tape) max. test pressure: ≤500kPa;

7 . Emitter spacing : 100mm~300mm;

8. Emitter diameter: Φ12mm, Φ16mm, Φ18mm, Φ20mm;

9. 10’’ touch screen human-computer interaction, test report is saved on U flash disk & be edited on computer;

OUR SERVICE

We have 20-year expericen design team

We have professional QC team to ensure product quality

We have skilled staff to provide you perfect finished products

We provide you ontime aftersale service