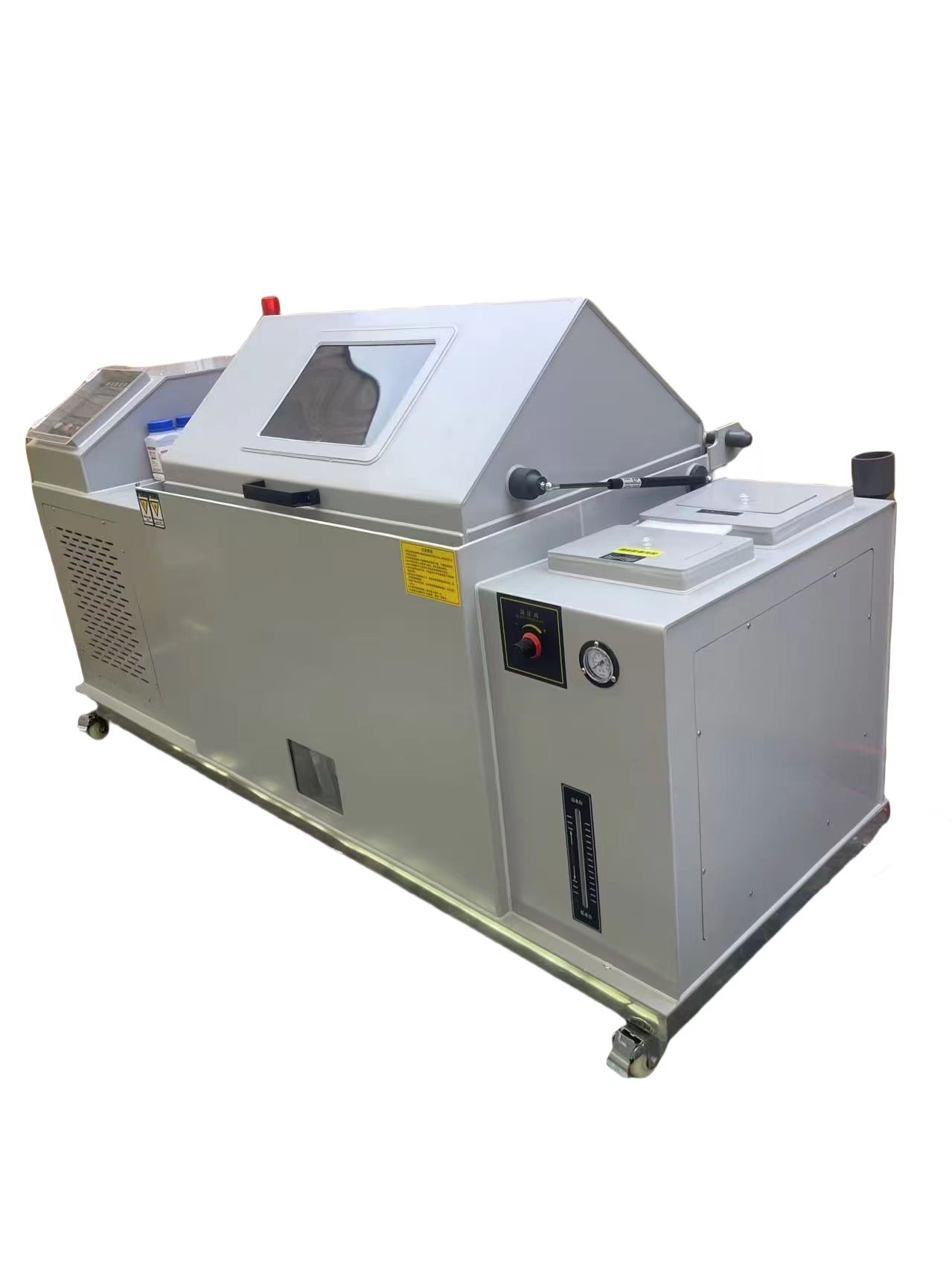

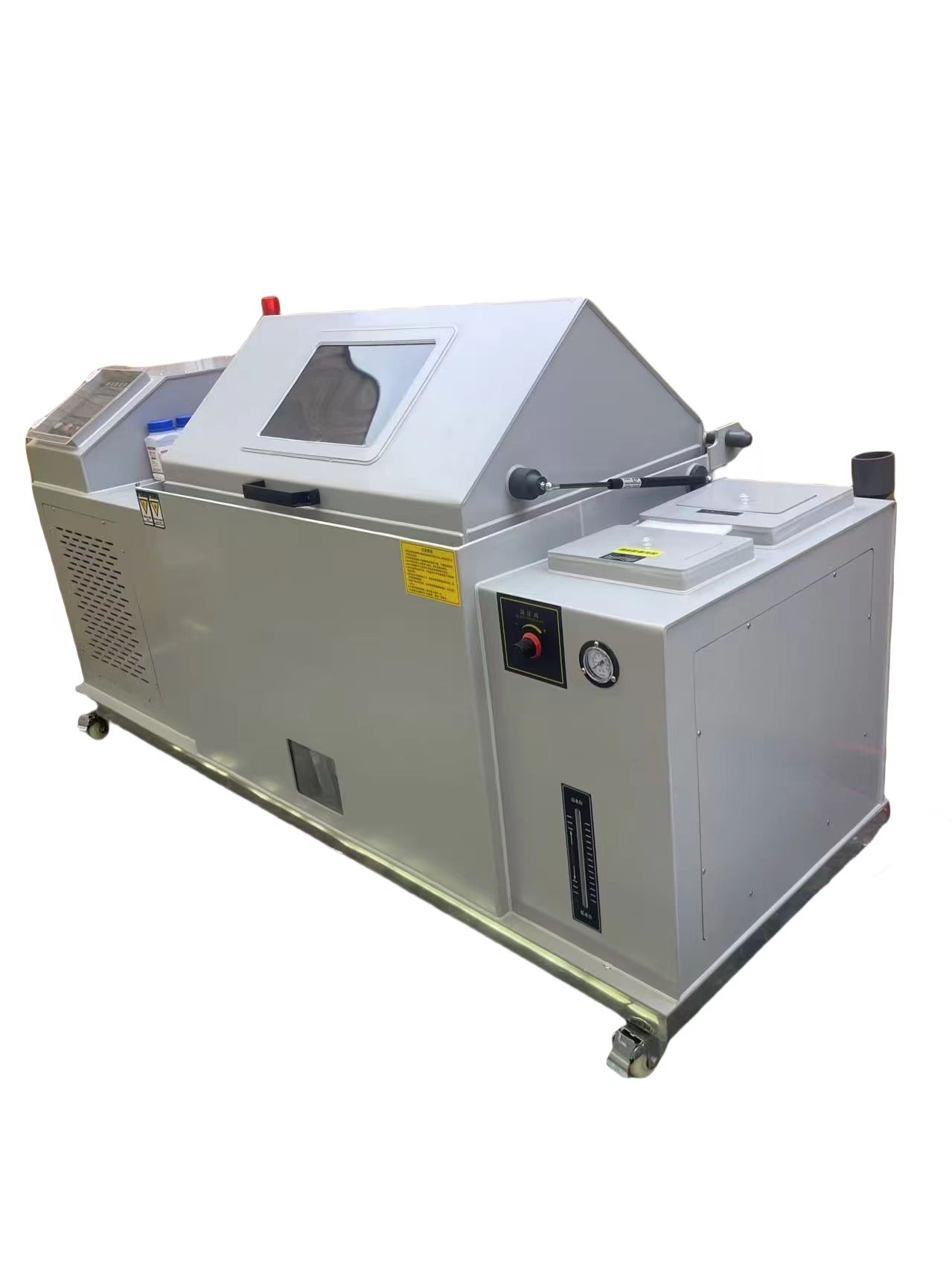

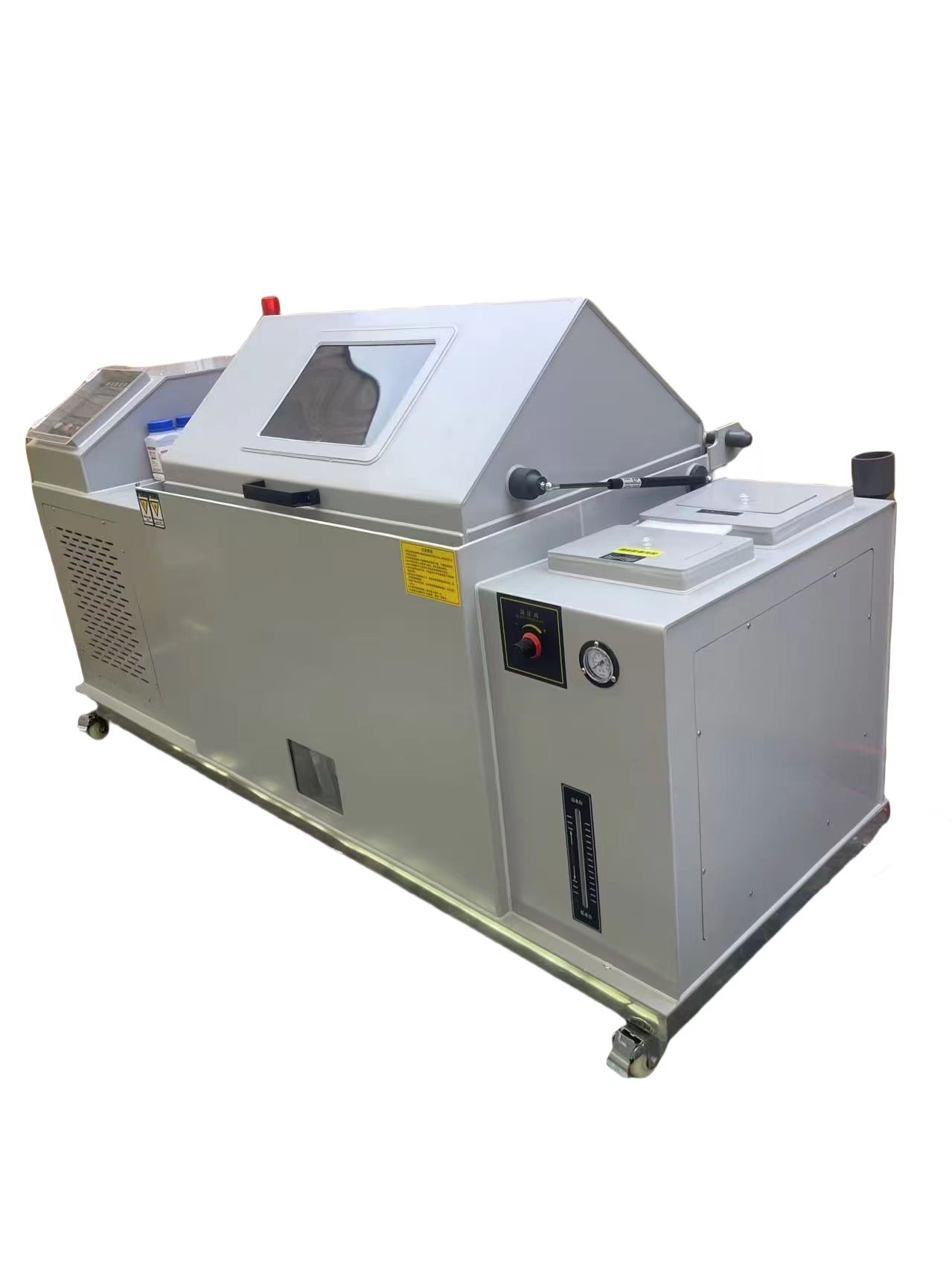

Application

Aacid salt spraying chamber is a type of corrosion test chamber used to evaluate the corrosion resistance and durability of materials and coatings. It creates a controlled environment of acidic salt fog, which accelerates corrosion conditions. This allows manufacturers to make informed decisions and improvements in product design, material selection, and coating techniques.

It is important to note that the results of salt spray testing shou

ld be interpreted with care, as they provide an accelerated representation of corrosion and do not necessarily reflect real-world conditions

The most commonly used standard for salt spray testing is ASTM B117, although other standards like JIS Z 2371, ISO 9227-2017, and ASTM G85 are also relevant 8.

Features of chamber body

8mm thickness chamber body and sealing cover adopts special design technology, it will not deform at high-temperature.

Specimen platform is made of 8mm temperature resistant ABS board with strong load-bearing capacity, test specimen frame can be adjusted at any angle, fog from each side fall uniformly and consistent, test results are of high accuracy.

Adopt automatic and manual modes of water filling system, automatic or manual replenishment of the pressure vessel and test chamber, to prevent water shortage or ultra-high temperature damage to the machine.

Defog the salt spray in the test chamber during the test process and shutdown to prevent corrosive gases flowing out and damaging other precision instruments.

Features of Spraying system

Adopting Bernoulli principle to absorb salt water and atomized, with high atomization uniformity, without crystallization phenomenon.

Special glass nozzle: can adjust the spray volume and spray angle.

Spray volume can be adjusted between 1ml/h to 2ml/h

Spray mode: continuous spray

Technical Parameters

1. Inner dimension: 900x600x500mm

2. Temperature in the test chamber: 35℃ ± 1℃

3. Tct GT