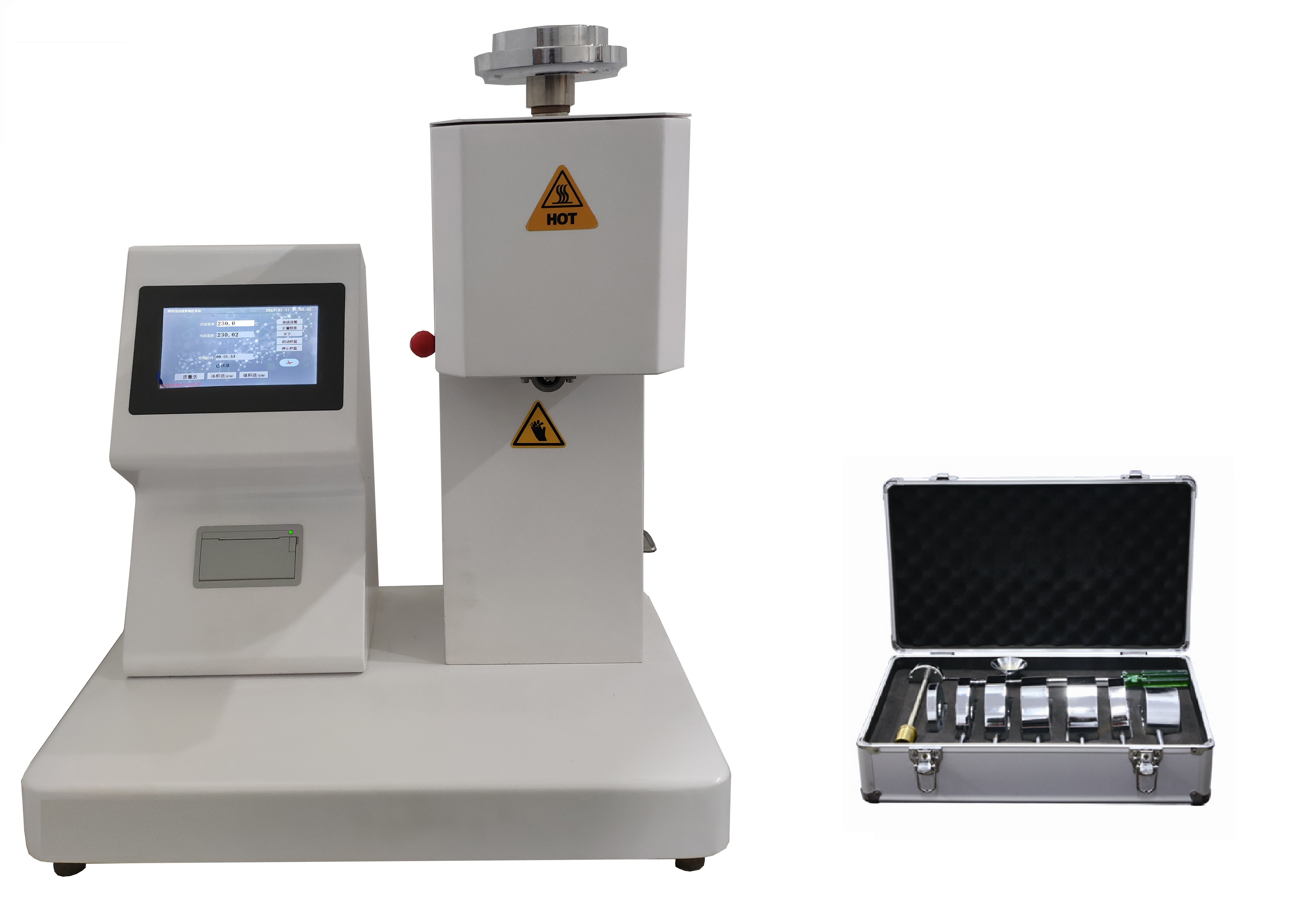

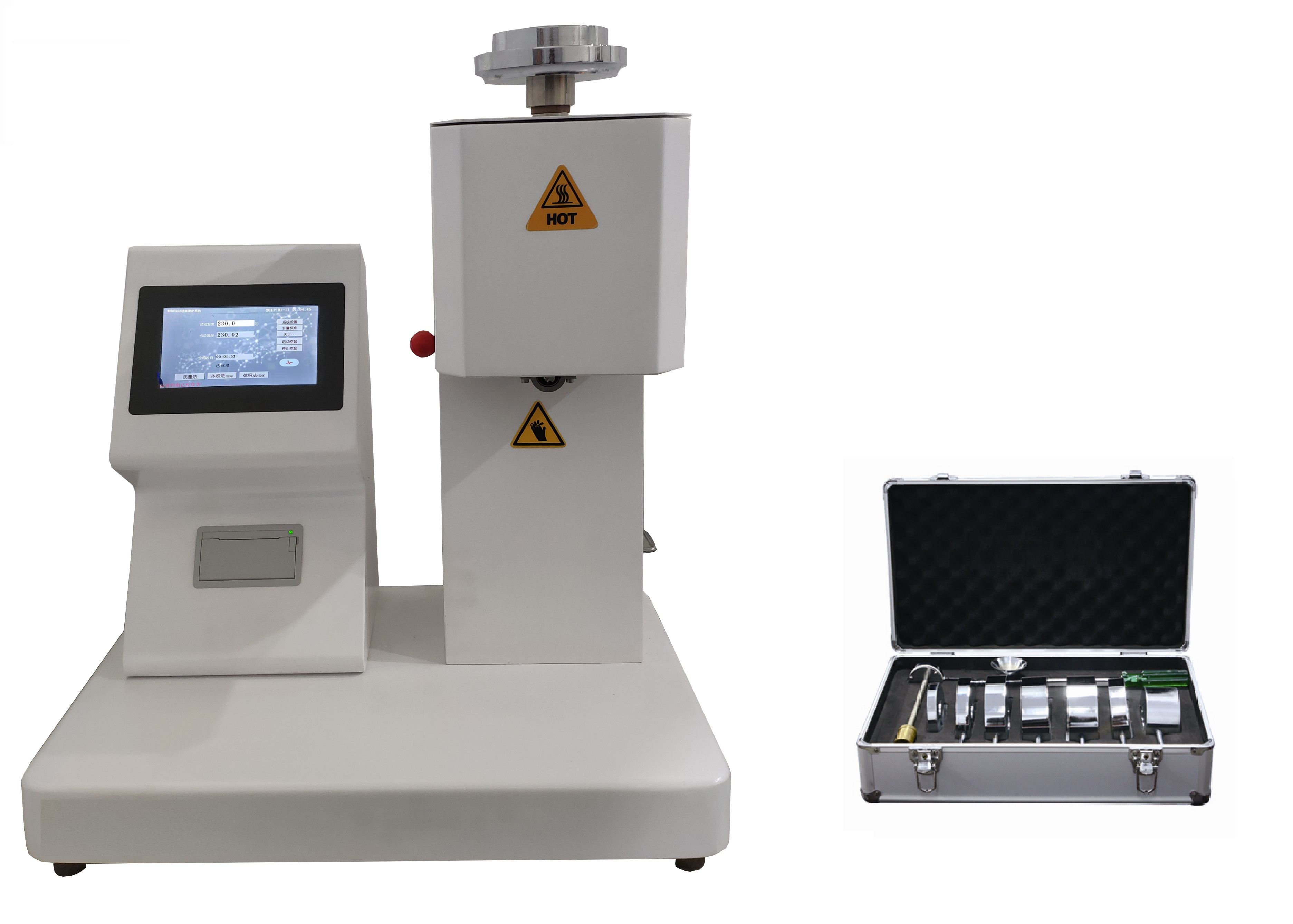

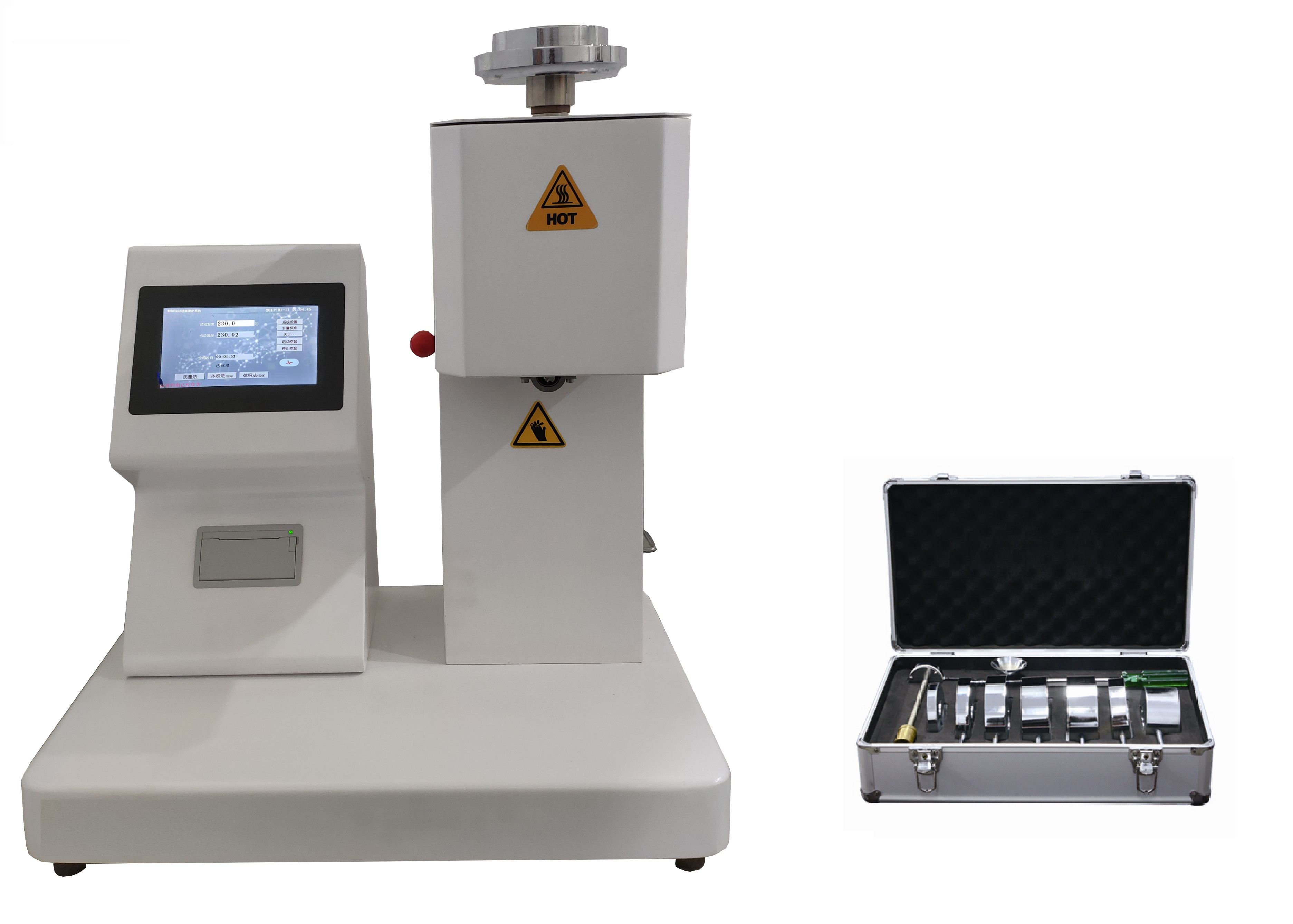

Product Overview

The GT-MFI-450D Melt Flow Indexer is a cutting-edge tabletop instrument designed to measure the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastic materials, adhering strictly to ISO 1133, ASTM D1238, and GB/T 3682 standards. This versatile device caters to a wide range of thermoplastic forms, including granules, film strips, and pellets, making it an essential tool for quality control in polymer manufacturing, raw material testing, and research laboratories.

Unlike conventional flow testers, this model combines affordability with high precision, enabling accurate comparisons between filled and unfilled thermoplastics, as well as materials with varying filler contents. Its ability to calculate melt density (when melt density at test conditions is known) adds significant value for material characterization, ensuring consistent product quality across production batches. Whether used in small-scale workshops or large industrial facilities, the GT-MFI-450D delivers reliable data to support informed decision-making in material selection and process optimization.

Product Specifications

Parameter | Details |

Model | GT-MFI-450D |

Operating Temperature | 50℃ to 450℃ |

Temperature Control Accuracy | ≤ 0.2℃ |

Temperature Display Resolution | 0.1℃ |

MVR Displacement Accuracy | 0.02mm |

Temperature Recovery Time | < 4 min |

Power Supply | 220V 50Hz |

Communication Ports | RS485 / USB |

Measurement Range | MFR: (0.1-100)g/10min; MVR:(0.01-350)cm³/10min |

Weight Capacity | Up to 21.6kg |

Design

Control System

The GT-MFI-450D features a dual-control design, integrating a 7-inch color touch screen with PC-based software for seamless operation. The touch screen provides intuitive access to real-time data, while the PC software offers advanced functionalities such as parameter configuration, test data storage, and result export in multiple formats (Excel, PDF). This hybrid control system ensures flexibility for both on-site operators and remote monitoring needs.

Precision Engineering

Equipped with a high-sensitivity displacement sensor, the instrument achieves MVR displacement accuracy of 0.02mm, ensuring precise volume flow measurements. The built-in automatic cutting mechanism triggers at preset intervals with a timing error of ±0.1 seconds, eliminating human error in sample collection. Rapid heating elements enable the device to reach set temperatures quickly, with minimal overshoot, and maintain temperature control accuracy of ≤ 0.2℃ for consistent test conditions.

Safety & Durability

To prevent unauthorized adjustments, critical operations (e.g., calibration, parameter reset) require password verification. The instrument also includes over-temperature protection, audio alerts for temperature stability, and automatic shutdown safeguards, ensuring safe operation in industrial environments. Its robust stainless-steel cylinder and piston rod resist corrosion from molten plastics, extending service life even with frequent use.

Custom Service

OEM Solutions

We offer OEM services tailored to specific brand requirements, including custom logos, packaging, and user manuals. Clients can request modifications to software interfaces to align with their existing quality management systems, enhancing operational integration.

Customized Configurations

While the standard package includes weights up to 21.6kg, additional weights (up to 50kg) are available for specialized testing needs. For unique thermoplastic materials, we provide customized die sizes and cylinder coatings to optimize compatibility with high-viscosity or abrasive melts.

Technical Support

Our team offers pre-sales consultation to determine optimal test parameters for specific materials, as well as on-site installation and training. Post-purchase, clients receive 24/7 technical support via email and video calls, with replacement parts shipped within 48 hours for urgent repairs. Software updates are provided free of charge for the first three years, ensuring the instrument remains compatible with evolving industry standards.