Carbon black dispersion tester in rubber and PE

Carbon black dispersion tester in rubber and PE

Standards

GB/T 6030-2006

ASTM D 2663-14

Application

GT-CBD-1000A is mainly used to detect the dispersion level of carbon black in rubber, that is, the dispersion status and dispersion uniformity of carbon black in rubber, which directly affects the properties of rubber, such as rubber tearing strength, tear performance, fatigue performance, wear resistance.

It is of great significance to quickly and accurately grasp the dispersion of carbon black in rubber materials for predicting the physical properties of rubber materials, controlling mixing process, ensuring the quality of rubber products, improving production efficiency, saving energy and reducing costs.

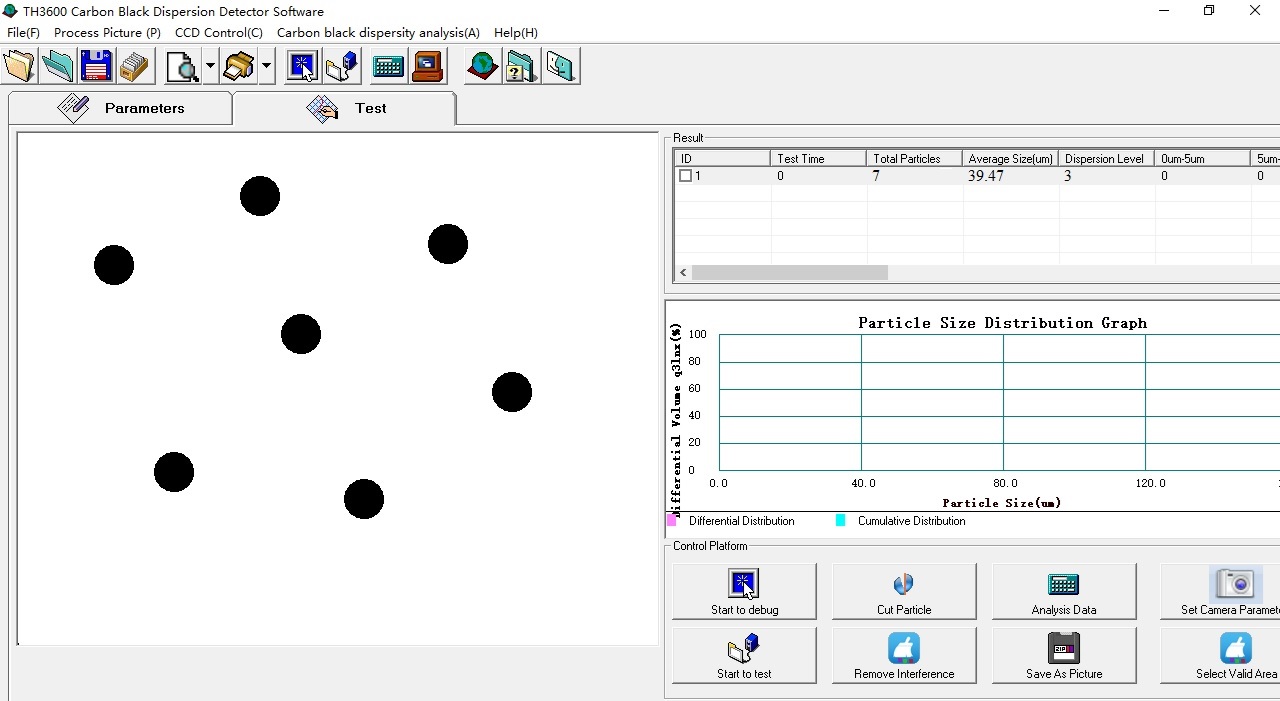

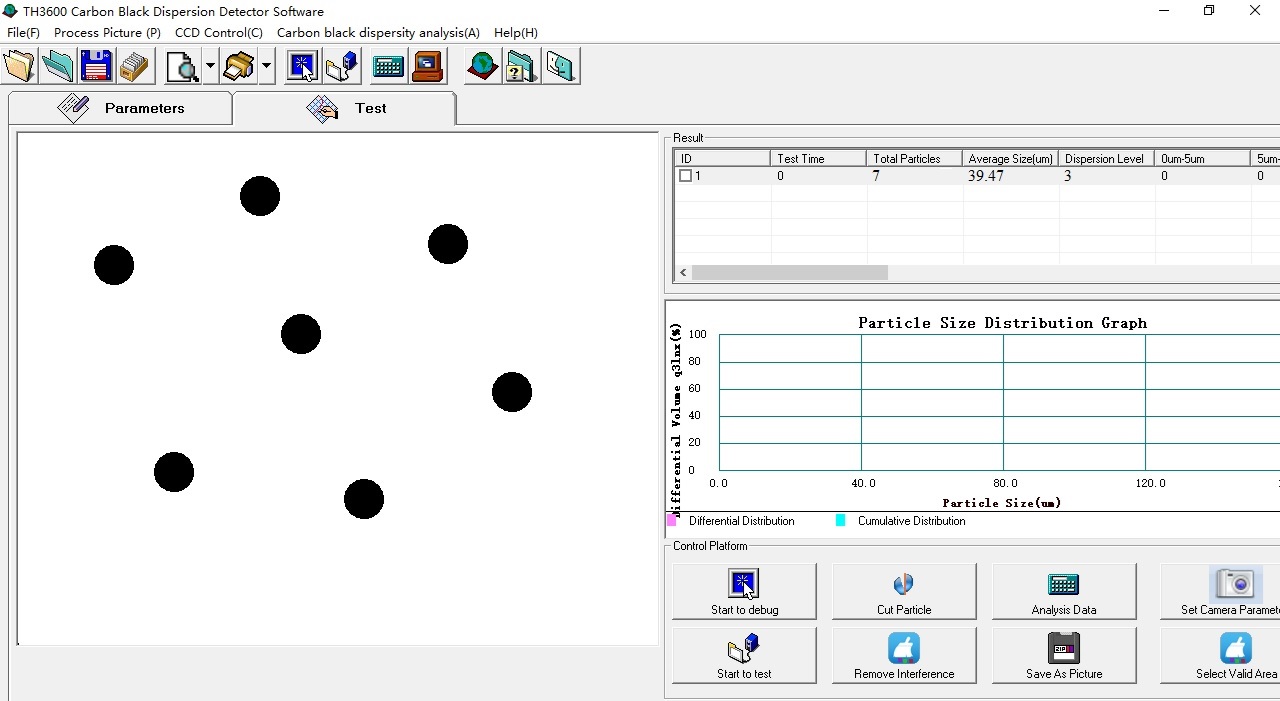

Software realizes the automatic collection of particles images, automatic storing date, automatic calculation of parameters.

Features

1. High resolution CCD camera, with powerful software support, can fast and accurately measure the size of the particles and its dispersion.

2. A wide range of particle size distributions, ranging from the micron to the millimeter.

3. 3 million pixel CMOS image sensor, the image resolution is greatly improved.

4. Arbitrarily adjustable 30 degree oblique light source intensity.

5. Convenient segmentation adhesion particles, the mouse around the click can be divided into arbitrary adhesion particles.

6. Convenient to remove the interference particles, the mouse around the click can remove any interference particles

7. USB data interface is adopted, which is more compatible with microcomputer. The instrument is separated from the computer and can be equipped with any computer with USB interface; Desktop, laptop, mobile PC are available.

8. May save a single particle image, can also save a series of measurement pictures.

9. The measurement results are very convenient, the distribution diagram of carbon black particle dispersion size is calculated automatically, and the carbon black dispersion grade is given automatically.

10. Software personalization, provide measurement wizard and many other functions, easy for users to operate; The output data of measurement results is rich and stored in the database, which can be used for call analysis with any parameters, such as operator name, sample name, date, time, etc., to share data with other software.

11. Standard samples are provided to calibrate each magnification.

Technical Parameters

1. Measurement principle: image analysis method

2. Measurement range: 0.5μm to 10,000μm

3. Measurement and analysis time: less than 3 minutes under normal conditions

4. Reproducibility: 3%

5. Particle size equivalence principle: equal area circle diameter and equivalent short diameter

6. Size statistics: volume (weight) and number of particles

7. Calibration method: through the standard sample, different magnification rate correction, non-interference

8. Imaging resolution: 2048x1536 (3 megapixel digital camera ,5 megapixel optional)

9. Image size: 1280 x 1024 pixels

10. Optical magnification: 0.8X,1X,2X,3X,4X, 5X

11. Total magnification: 24X,30X,60X,80X,100X, 120X

12. Automatic analysis results: dispersion grade, average particle size, number of particles, particle data corresponding to different particle size intervals (number, differential %, cumulative %), histogram of particle size distribution

13. Output format: Excel format, JPG format, PDF format, printer and other display methods

14. Data report format: it can be divided into "picture data report" and "data distribution report"

15. Sample station: φ100mm

Carbon black dispersion tester in rubber and PE

Carbon black dispersion tester in rubber and PE