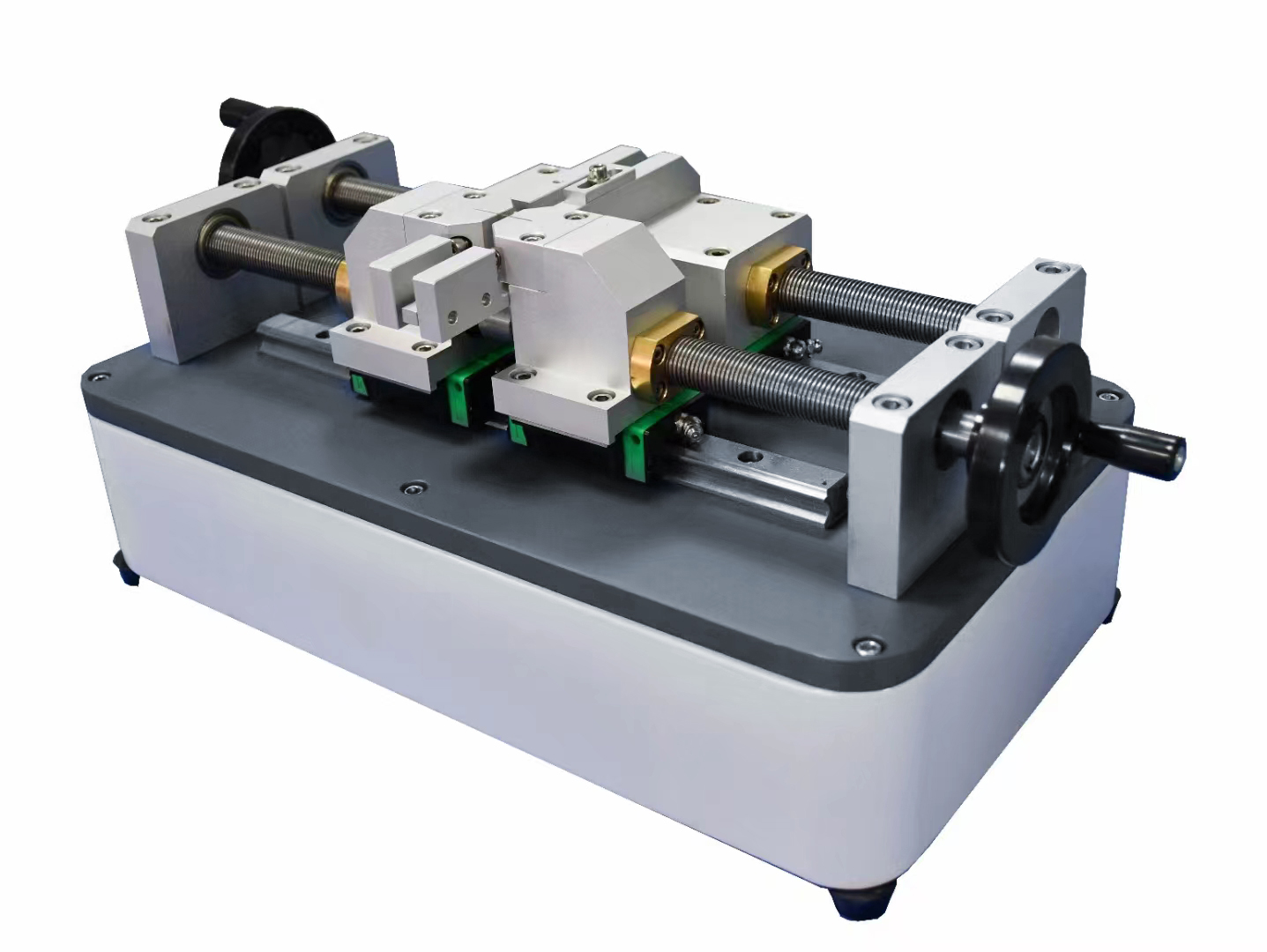

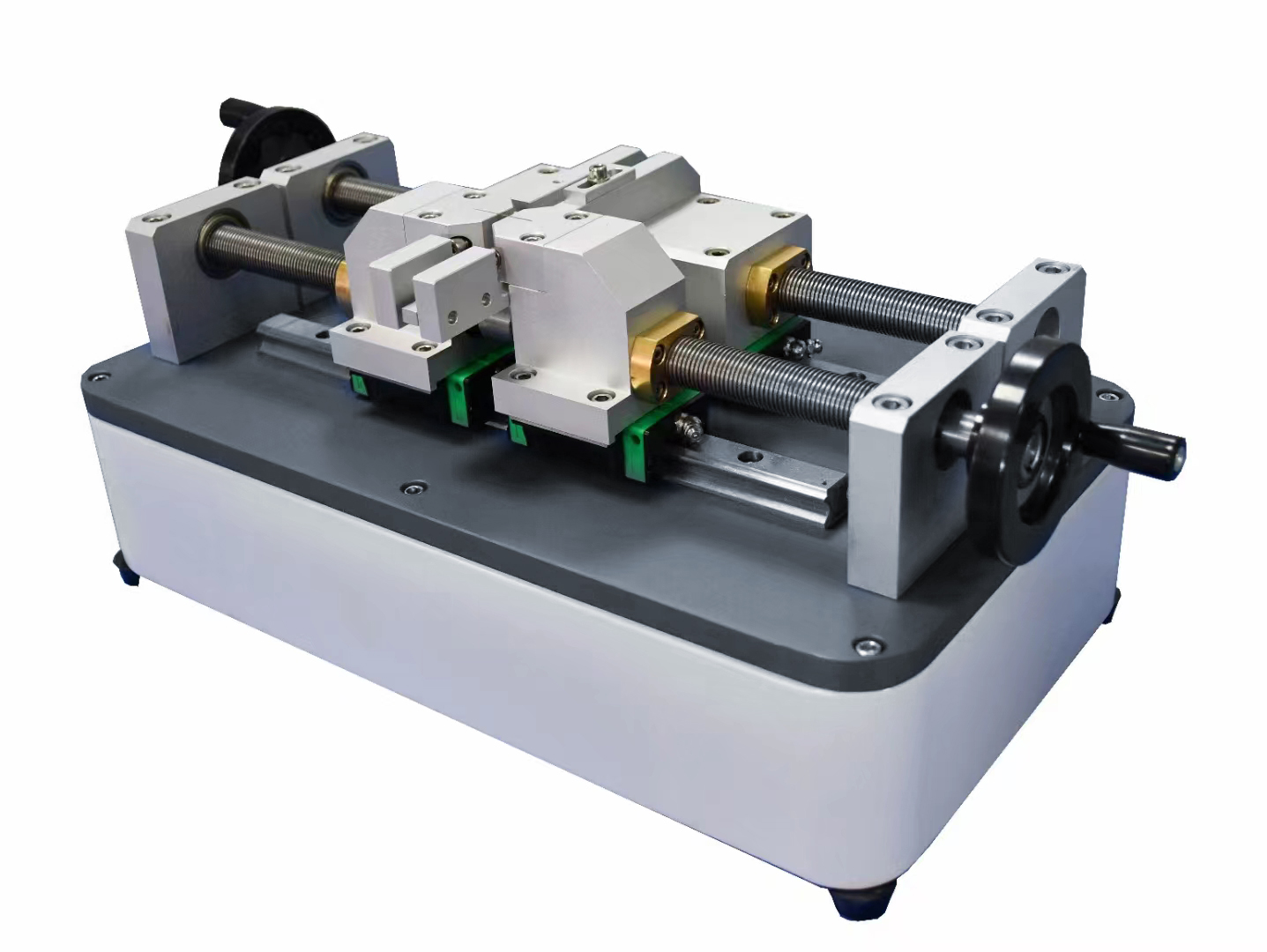

Coplanar Double Notch Making Machine

Standards

GB/T18743.2-2022

ISO 9854

ISO16770-2004

ASTM F 1473

Application

This tester is used to make double-notches on the ultra-high molecular weight polyethylene (PE-UHMW) molding material specimen, using it along with 50J pipe charpy impact tester for the determination of double-notched charpy impact strength of PE-UHMW molded materials.

It is also applicable for notch preparation of FNCT and PENT specimens.

Features

1. May accomplish the preparation of two sides of the coplanar notch in one time.

2. The unique structure design makes the notches and specimen centerline strictly coincident.

3. The electronic micrometer is used for measuring the notching depth, largely guarantees the accuracy and consistency of both remaining width of the specimen.

4. Double knives cutting & double knives synchronization: in the notching process, the cutting force on both sides of the specimen is same, and the deformation at radial direction is invisibly.

5. The knife blade is only subject to axial force without any lateral force, which largely increase the knife lifetime.

Technical Parameters

1. Knife thickness: 0.23mm±0.03mm

2. Blade cutting angle: 14°±2°

3. Blade width: 19mm

4. Clamp opening range: 2mm to 20mm

5. Specimen length range: 80mm to 120mm

6. Residual width accurate: ±0.02mm

7. Notch accurate: ±0.02mm

8. Notch depth: 5.5,4.3,4,3,1.3mm