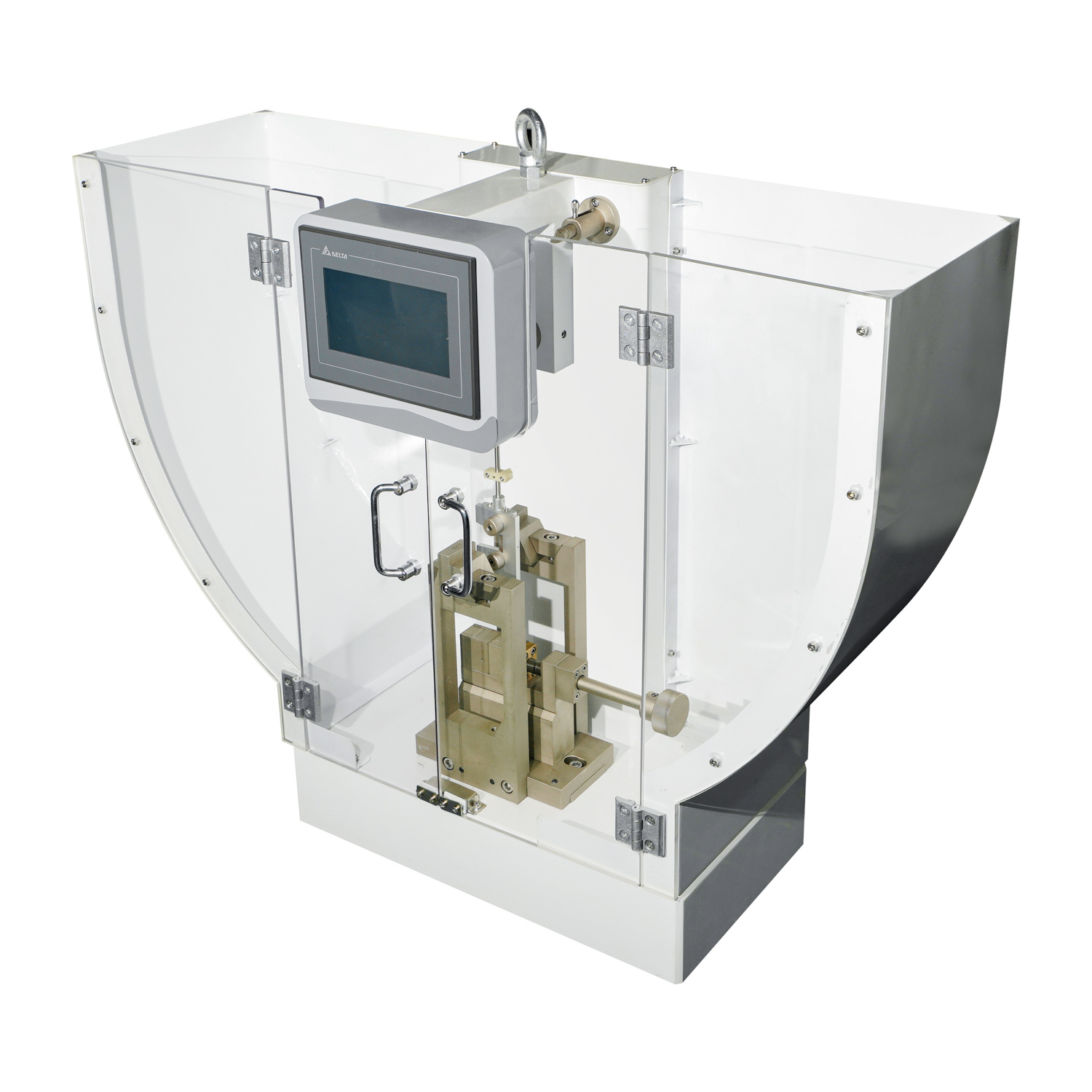

Semi-automatic Charpy Impact Testing Machine

The High-Quality and Cost-Effective Plastic Cantilever Beam Impact Testing Machine is designed to test the impact resistance of plastics. It can perform two types of impact methods: cantilever beam impact (CHARPY) and IZOD impact. The machine automatically calculates the air resistance and impact energy during the entire testing process, providing important guidance for material research and production processes.

The charpy and IZOD impact tester is a versatile and reliable tool for evaluating the impact resistance of various plastic materials. It is widely used in industries such as automotive, engineering plastics, and plastic pipe manufacturing.

The machine is capable of conducting both cantilever beam and Izod impact tests, allowing for comprehensive evaluation of a material's impact performance. This flexibility enables manufacturers to assess the suitability of plastics for different applications and make informed decisions during the material selection process.

The testing machine is equipped with advanced sensors and control systems that automatically calculate air resistance and impact energy. This automation ensures accurate and consistent test results, reducing human error and improving testing efficiency.

The Plastic Cantilever Beam Impact Testing Machine is designed with high-quality components to ensure durability and long-lasting performance. It is built to withstand the rigors of repetitive testing and can be relied upon for consistent and reliable results.

Standards

l ISO 179 Part 1 (non-instrumented impact test).

Application

Charpy pendulum impact tester is used to conduct resilience tests on rigid plastic materials in order to determine their impact fragility characteristics under standard stress conditions. The test method conforms to ISO 179 - Part 1 (non-instrumented impact test).

The sample, supported near its ends as a horizontal beam, is impacted by a single blow of a striker, with the line of impact midway between the supports, and bent at a high, nominally constant, velocity.

Izod method is used to investigate the behavior of specified types of specimen under impact conditions defined and for estimating the brittleness or toughess of specimens within the limitations inherent in the test conditions.

The test specimen, supported as a vertical cantilever beam, is broken by a single impact of a striker, with the line of impact a fixed distance from the specimen clamp and, in the case of notched specimens, from the centerline of the notch.

Features

l Impact speeds of 2.9m/s & 3.8m/s as well as multiple impact energies can be generated by one pendulum.

l High mass, traditional pendulum design concentrates energy at the impact point with minimal energy loss due to vibration.

l The electrics contain a high-resolution encoder for accurate measurement of the impact angel.

l Touch screen control for quick and easy input of parameters

l Results are automatically corrected for energy loss due to air and mechanical friction.

Technical Parameters

Energy levels (max capacity): 1J, 2J, 4J and 5J (Model: CIT-5) / 15J, 25J, 50J (Model: CIT-50)

Span of Charpy: 62mm

Charpy testing impact speed: 2.9 m/s (Model: CIT-5); 3.8m/s (Model: CIT-50)

Izod Energy levels (max capacity): 5.5J, 11J and 22J

Izod testing impact speed: 3.5m/s

Measurement resolution: 0.01J

Measurement resolution: 0.01J

Notch A: 45º±1º Radius of the notch bottom, R=0.25±0.05mm

Notch B: 45º±1º Radius of the notch bottom, R=1±0.05m

Notch C: 45º±1º Radius of the notch bottom, R=0.10±0.02mm