Differential Scanning Calorimeter at High Pressure

Standards

· ISO11357-6, Isothermal OIT and Dynamic OIT (OOT)

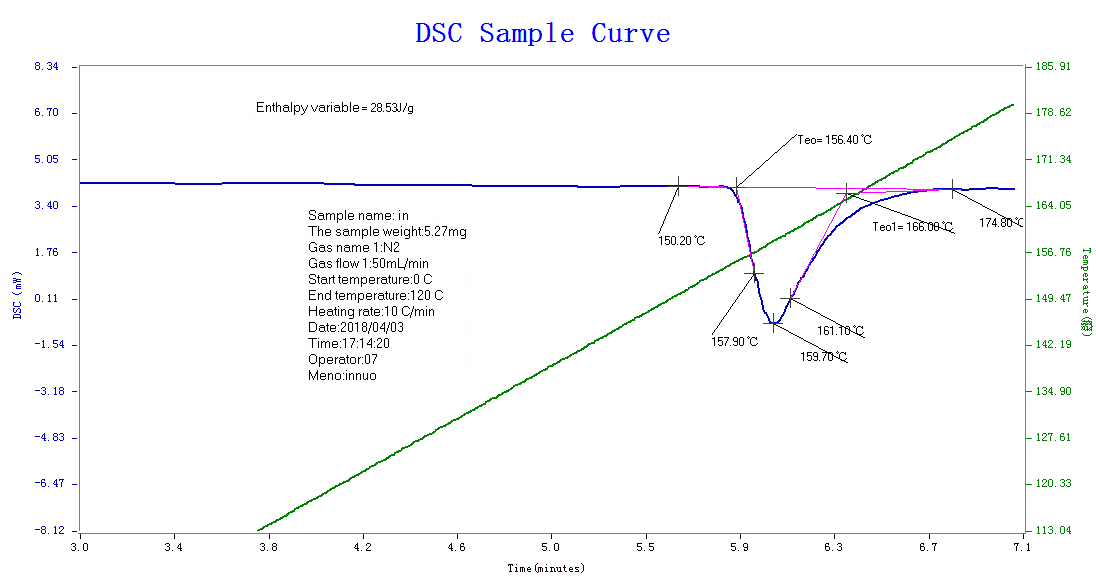

· ISO11357-3, Enthalpy of melting and crystallization

· ISO11357-2, Glass transition temperature

· ASTM D5483-02

Highlights

Test at 3/5Mpa high pressure

Touch screen + computer control

Software Full-automatic performance

Functions

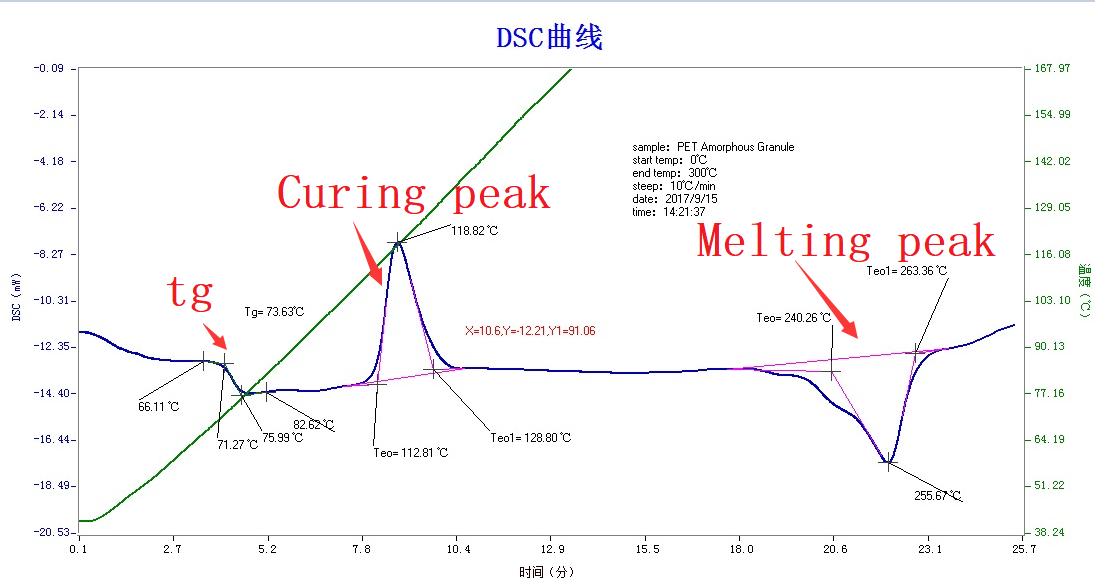

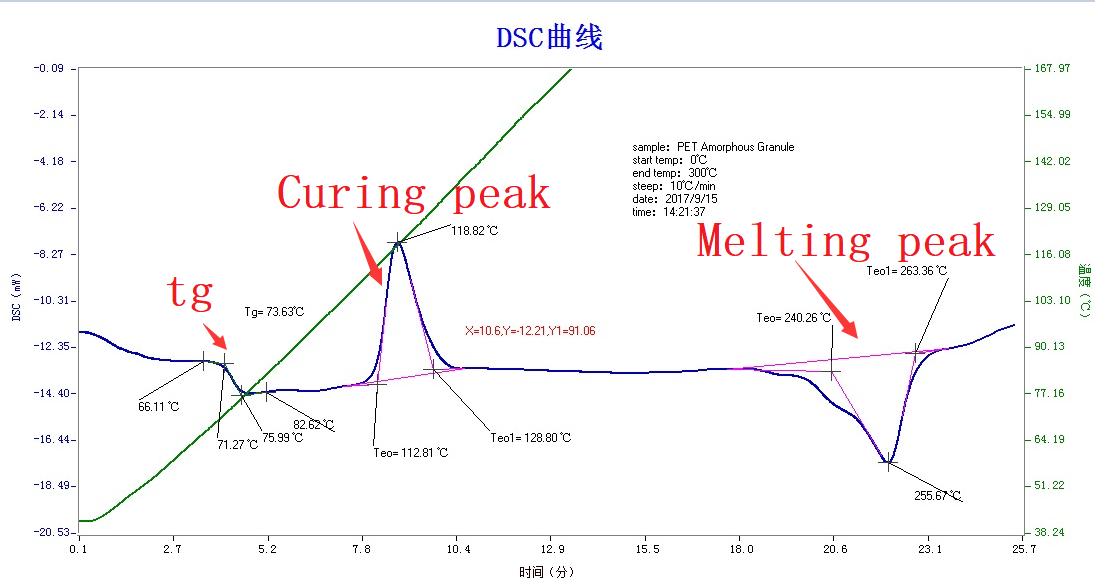

1. Glass transition temperature

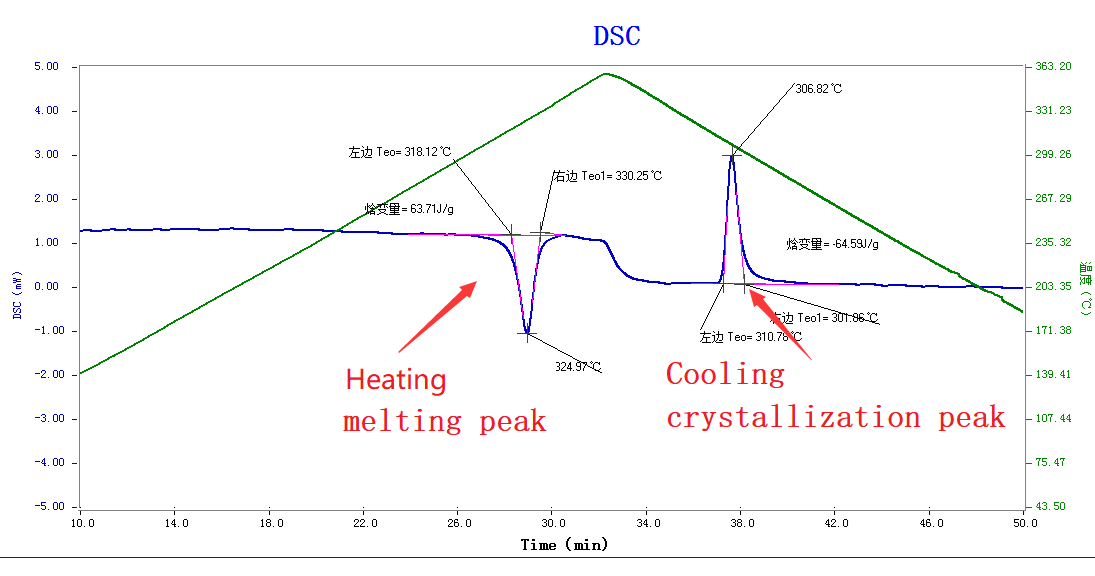

2. Phase transition

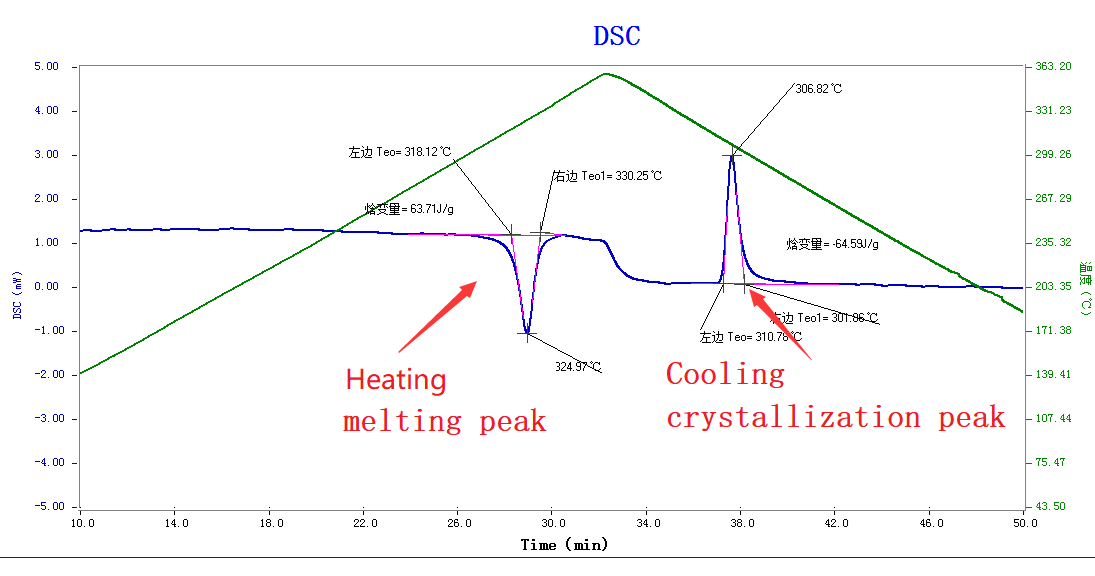

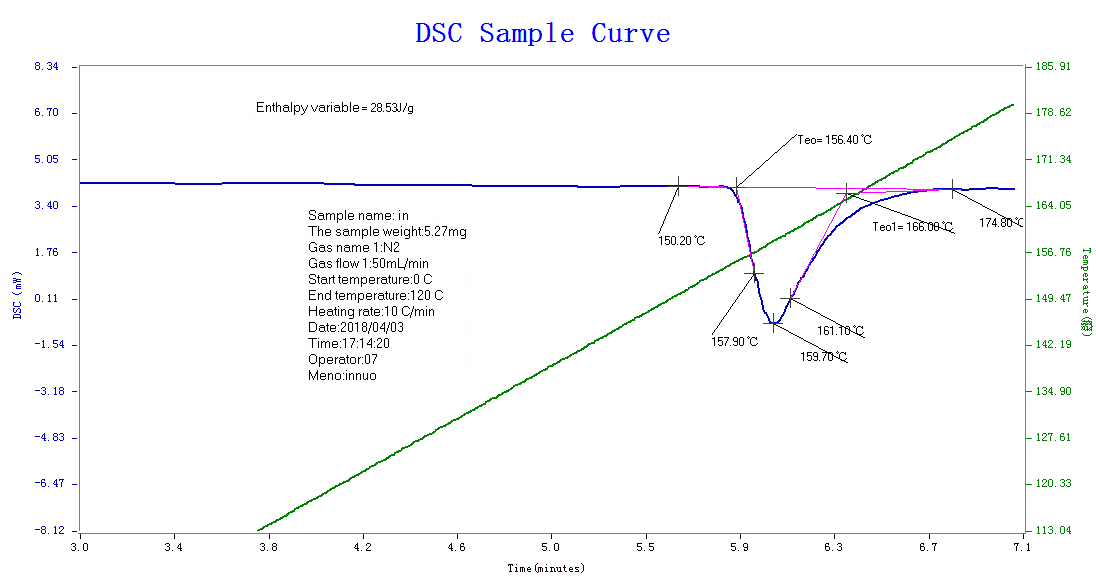

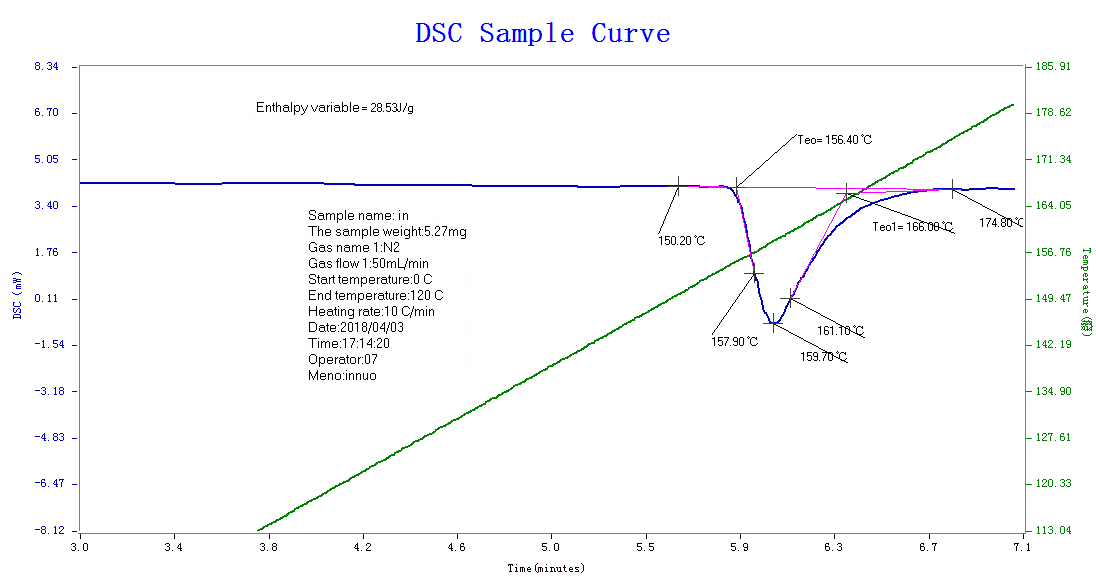

3. Temperature and Enthalpy of melting and crystallization

4. Oxidation induction time (OIT)

5. Oxidation induction temperature (OOT)

6. Melting point

Application

DSC is an intelligent and miniaturized thermal analysis instrument, which is applicable for oxidation induction time(OIT) test, Oxidation induction temperature (dynamic OIT, also call OOT), as well as Glass transition temperature, Phase transition, Temperature and Enthalpy of melting and crystallization.

It provides an analysis method for organic, inorganic, polymer, mineral, petrochemical products, textile, medicine, etc. Functions like magnification and narrowing of the graph make the friendly interface easy to operate.

Features

Computer is introduced with rich information, e.g. temperature setting, sample temperature, Oxygen flow rate, Nitrogen flow rate, DSC signal etc.

Integrated furnace, user-selectable rate for temperature rising up/down.

Double temperature sensors ensure high repeatability of test results. One sensor installed on the wall of furnace, the other at the bottom of sample for collecting real test temperature. Patented controlling technology is applied to make the temperature of the sample reach to the set point by controlling the temperature on the wall of the furnace.

Digital mass-flow meter switches the flow rate of Oxygen/Nitrogen automatically with fast switching speed.

Standard sample provided for calibrating constant temperature coefficient.

Simplified to one-key operation. Tens of commands can be combined on your demands, making operation more easier. Also support self-programming function.

With standard material (indium, tin, zinc), users can adjust the temperature coefficient and enthalpy value coefficient by themselves.

The acquisition, storage and display of the data curve, result report including temp calibration and correction, extension of initial temp, enthalpy variables, glass transition temp, enthalpy change ratio (the reaction conversion), oxidation induction time(OIT), and the processing of dynamic parameters, etc.

Technical specifications

1. Temperature range: Room temperature to 500℃ (800℃ available)

2. Temperature resolution:0.01℃

3. Heating rate: 0.1 to 80 ℃ / min

4. Cooling rate: 0.1 to 20℃/min

5. Gas pressure: ≤3MPa (GT-DSC-HP3) or ≤5MPa (GT-DSC-HP5)

6. Pressure accuracy: 0.2Mpa

7. Temperature control mode: Heating, cooling, constant temperature, any combination of three modes cycle use, temperature uninterrupted

8. DSC range: 0 to ±500mW

9. DSC resolution: 0.01mW

10. DSC sensitivity: 0.1mW

11. Atmosphere control gas: Two-channel gas control by automatic controlled

12. Gas flow:0-250mL/min

13. Calibration standard: with standard material (indium, tin, zinc), users can adjust the temperature coefficient and enthalpy value coefficient by themselves

14. Display mode: Touch screen and PC

15. Fully closed support structure design, prevent items falling into the furnace body, pollution of the furnace body, reduce the maintenance rate

16. Working power: AC 220V 50Hz 300W