The practical significance of Differential Scanning Calorimeter (DSC) for testing polyethylene in the laboratory:

1. **Material characterization**: DSC is capable of accurately determining key thermal property parameters such as melting point, crystallinity, glass transition temperature, etc. of polyethylene. These data are essential for understanding the processing and use conditions of the material.

2. **Quality Control**: By monitoring the thermal behavior of polyethylene, it is possible to ensure consistency and stability from batch to batch, and detect possible problems with the raw material or production process in a timely manner.

3. **Processing Optimization**: Understanding the thermal properties of polyethylene can help develop optimal processing conditions, such as extrusion or injection molding temperatures, leading to improved productivity and product quality.

4. **New Material Development**: DSC is an important tool for studying the effects of new materials and additives on the properties of polyethylene, helping to drive material innovation and improvement.

5. **ENVIRONMENTAL IMPACT ASSESSMENT**: DSC can also be used to assess the thermal stability of polyethylene under different environmental conditions, such as long-term aging performance at high temperatures.

Strategies to convince customers to buy DSC equipment:

1. **Return on Investment Elaboration**: Explain how DSC can help the customer to improve product quality, reduce scrap rates, save on raw material costs, as well as avoid returns and legal risks due to quality issues.

2. **Competitive Advantage Emphasis**: Highlight DSC's capabilities in providing accurate material characterization data that can help customers stay ahead of technology in the marketplace.

3. **Technical Support and Service**: Commit to provide comprehensive technical support and service, including equipment installation, operation training and follow-up maintenance service, in order to reduce customers' operation difficulty and maintenance cost.

4. **Customized Solutions**: Provide customized DSC solutions according to customers' specific needs, demonstrating the flexibility and applicability of the equipment.

5. **Successful Case Sharing**: Provide successful cases of other customers in the same industry to prove the actual benefits and market recognition of DSC equipment.

Through the above strategies, the importance and value of DSC equipment in polyethylene inspection can be effectively communicated to customers, thus convincing them to make a purchase.

If you're involved in the field of materials science, then you're probably familiar with the oxidative induction time test. This test is used to determine the stability of a material when exposed to oxygen.

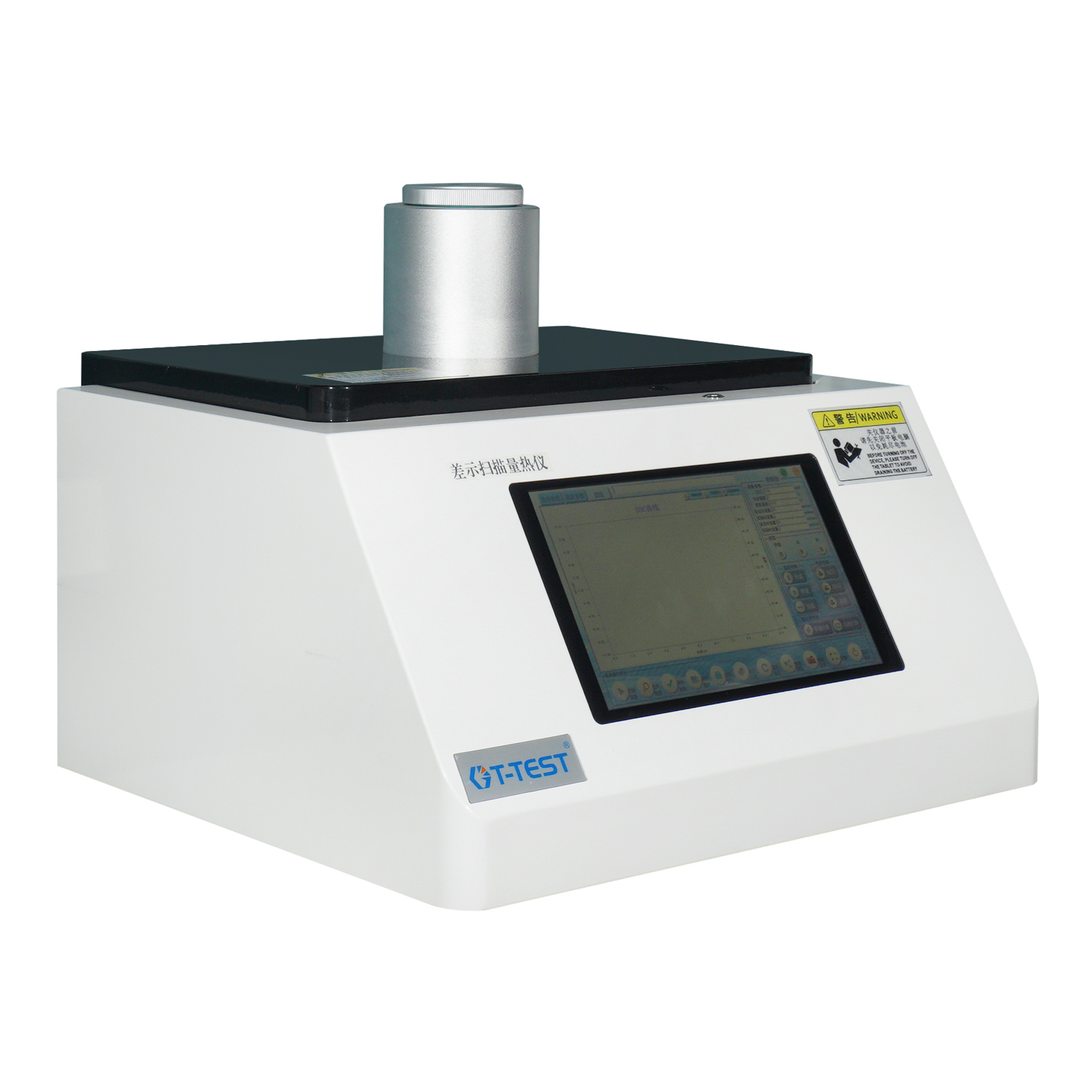

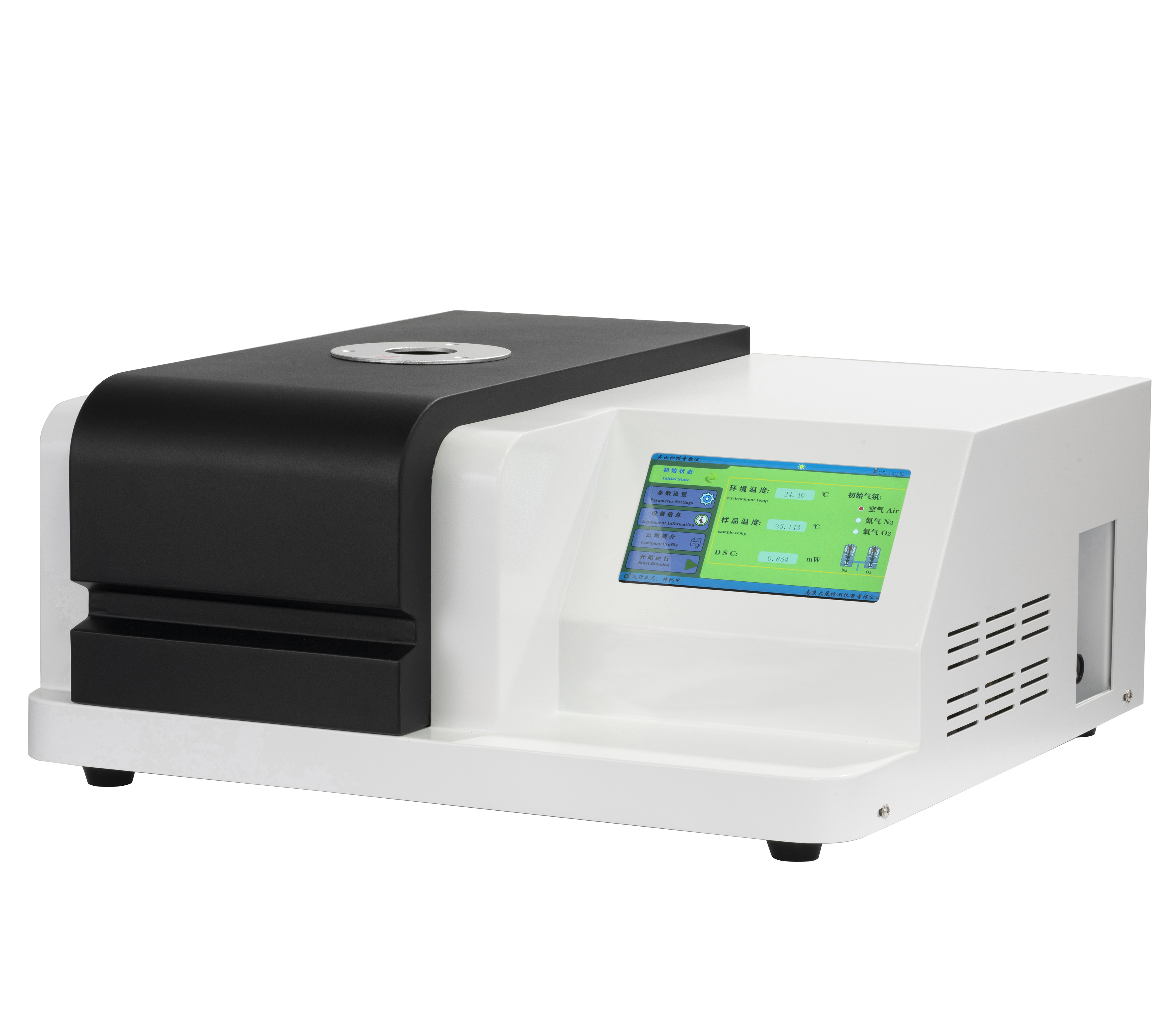

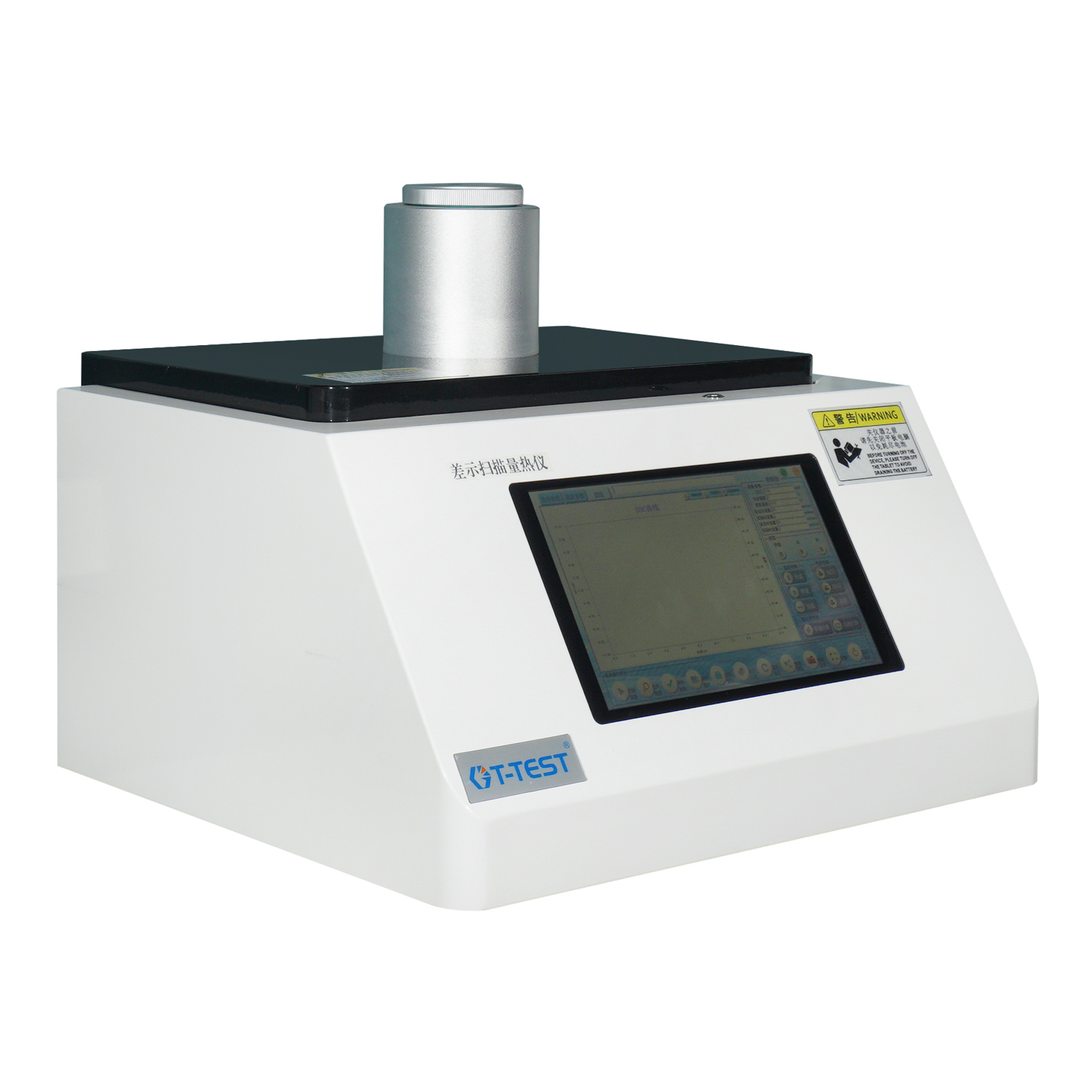

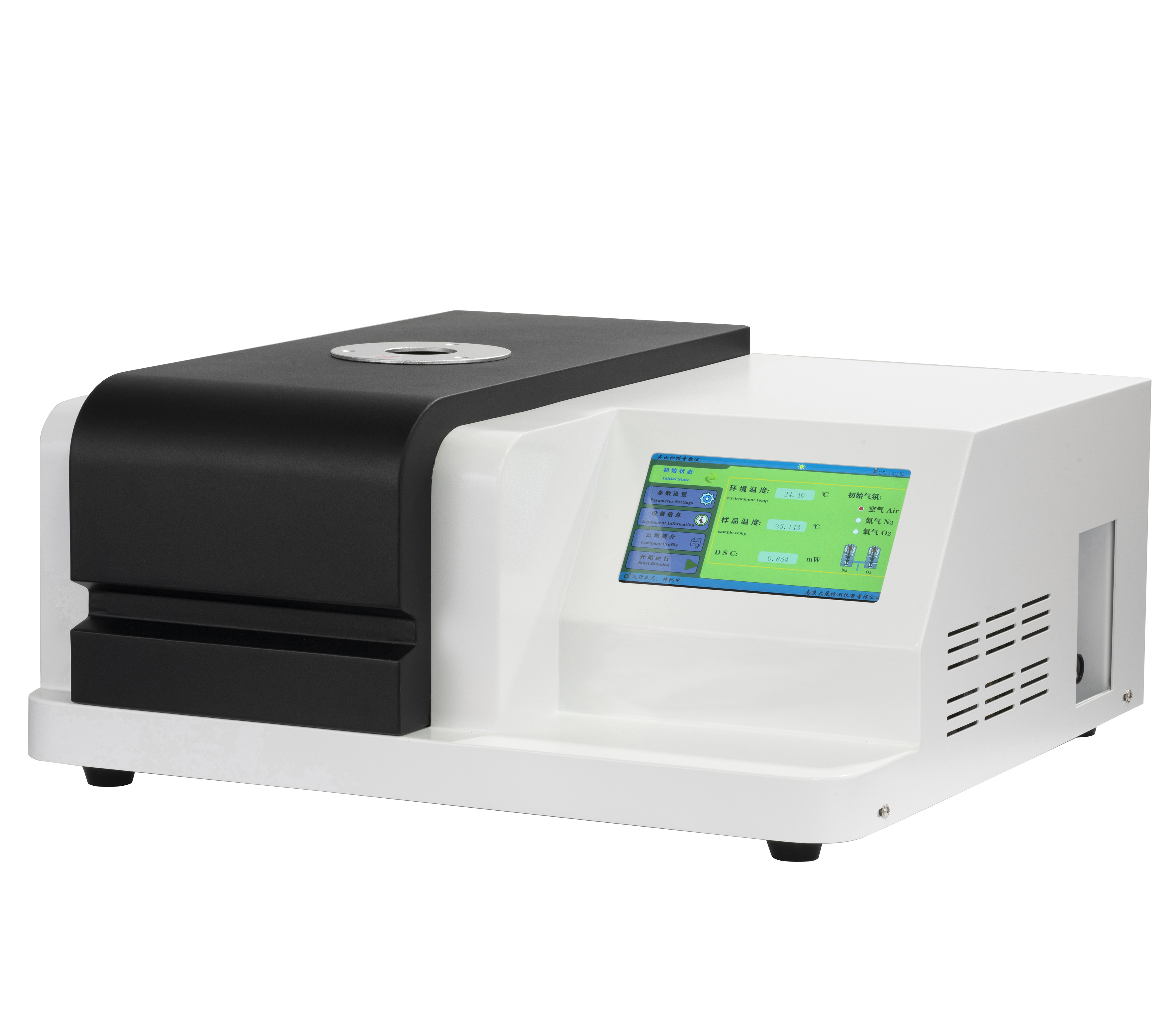

The oxidative induction time test equipment (DSC) is used to measure the rate of oxygen uptake by a material. The DSC measures the amount of heat generated by the oxidation reaction, and from this measurement, the induction time can be calculated.

There are many different types of DSCs on the market, so it's important to choose one that's suitable for your needs. In this article, we'll introduce you to some of the most popular types of DSCs and their features.

what is oxidative induction time test equipment(DSC)

The oxidative induction time test equipment, also known as DSC, is a piece of equipment used to measure the amount of time it takes for a material to undergo oxidation. This test is important for determining the shelf life of a material and can be used to compare different materials.

How do oxidative induction time test equipment(DSC) work

An oxidative induction time test is a type of equipment used to determine the induction time of oxidation in a material. The test measures the time it takes for a sample to change color when exposed to air. The equipment consists of a container with a lid, a stopwatch, and a light source.

To conduct the test, the sample is placed in the container and the lid is closed. The stopwatch is started and the container is placed in the light source. The time it takes for the sample to change color is recorded.

The results of the test are used to determine the oxidation resistance of the material.

What are the advantages of oxidative induction time test equipment(DSC)

There are many advantages to oxidative induction time test equipment (DSC). One advantage is that it can be used to determine the kinetics of reactions. Additionally, DSC can be used to study the relationship between structure and reactivity. Additionally, DSC can provide information about the mechanism of reactions.