Product Overview

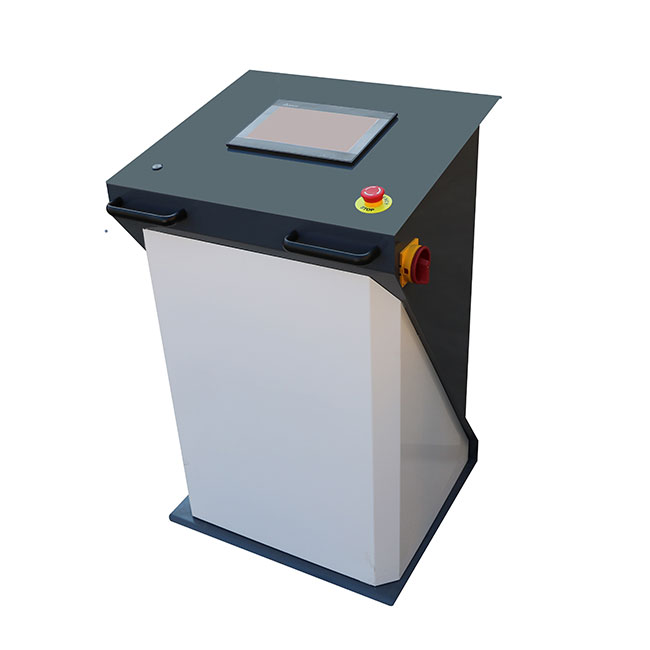

The GT-TEST Comprehensive Lab Bench (Code: 9024800000) is a state-of-the-art testing equipment designed to meet the rigorous requirements of modern irrigation system manufacturers and quality control laboratories. Compliant with ISO 9260 and ISO 9261 standards, this versatile bench serves as a one-stop solution for evaluating the performance of various irrigation components.

Its primary applications include determining flow uniformity, analyzing pressure-flow relationships, conducting hydrostatic pressure tests at both constant and high temperatures, performing burst tests on single-sided labyrinth drip irrigation tubes, and assessing compensating emitters. Additionally, it is highly effective for burst tests and hydrostatic pressure tests on low-pressure water supply irrigation PE soft tubes.

Equipped with advanced automation features, the bench minimizes manual intervention, ensuring consistent and reliable test results across multiple applications. This makes it an indispensable tool for manufacturers seeking to validate product quality, comply with international standards, and enhance the efficiency of their quality control processes.

Product Specifications

Parameters | Details |

Test station number | 5 (each station equipped with 5 sets of volume flow sensors) |

Volume flow measurement | Utilizes high-precision sensors (25 pieces for simultaneous measurement) |

Flow range | 1.00l/h ~ 3.60l/h |

Timing accuracy | ±0.1s |

Test pressure | 0 ~ 1200kPa |

Irrigation tube max. test pressure | ≤500kPa |

Pressure resolution | 1kPa |

Pressure fluctuation | ±2% |

Emitter spacing | 100mm ~ 300mm |

Emitter diameter | Φ12mm, Φ16mm, Φ18mm, Φ20mm |

User interface | 10’’ touch screen human-computer interaction |

Data management | Test reports saved on U flash disk, editable on computer |

Observation feature | Transparent window with electrical control |

Design

The design of the Comprehensive Lab Bench focuses on precision, efficiency, and user-friendliness, incorporating several key features:

Advanced Sensing Technology

The integration of unique intelligent volume flow measuring sensors enables direct and highly accurate volume flow measurement, outperforming traditional balance or load cell-based methods. This ensures that every test result is precise and trustworthy.

Multi-Function Integration

By combining multiple testing capabilities into a single unit, the bench eliminates the need for separate equipment for different tests. Whether it's flow uniformity, pressure-flow relationship, or hydrostatic pressure tests, this bench handles them all, saving laboratory space and reducing operational costs.

Automated Operation

Embedded with test programs aligned with various international standards, the entire testing procedure is fully automated. This not only reduces the risk of human error but also significantly increases test efficiency, allowing laboratories to process more samples in less time.

Robust Data Management

The system automatically saves test data and retains it even in the event of a power outage, ensuring no critical information is lost. It also performs automated information processing, calculating key metrics such as Mean Flow, Coefficient of Variation (CV), Deviation between Mean Flow and Rating Flow, and sorting 25 emitters automatically.

Energy Efficiency

A notable design highlight is the ability to recycle water used during testing through the volume flow sensor, promoting environmental protection and reducing water consumption, which is particularly beneficial for long-term operational cost savings.

Custom Service

At Golden Time Technology Development Limited, we understand that every laboratory has unique requirements. To cater to these specific needs, we offer a comprehensive range of custom services:

Product Installation

Our professional technical team provides on-site installation services, ensuring the bench is set up correctly and operates at optimal performance from day one. We also offer detailed training sessions for laboratory staff to familiarize them with the equipment's operation and maintenance.

OEM Service

We provide OEM services to meet specific branding and design requirements. Whether it's custom logos, modified interfaces, or tailored packaging, our team works closely with clients to deliver a product that aligns with their brand identity.

After-Sales Service

Our commitment to customer satisfaction extends beyond the sale. We offer a dedicated after-sales service team available to address any issues or concerns promptly. This includes troubleshooting, repairs, and replacement of parts, ensuring minimal downtime for your laboratory operations.